Wednesday, 6th October, 2021...

There comes a time in every ol' fart biker's life when the empty space in the garage has to be filled with yet another bike. Five is an odd number, six is so much better. I've never owned a VFR750 but I did sit on one, way back, in the showroom of Coburn & Hughes, in Luton. I would have bought it there and then if I'd have been on my own, but I wasn't... my wife was with me and thought that what money we had could be spent in better ways... ho hum.

For almost two years, we've been living with the Covid-19 pandemic and what with the restrictions on travel, socialising and stuff, I've managed to save a modest amount of cash. They say that every cloud has a silver lining. All the bikes I currently own are in fine running order and I need a new project to keep me occupied. Old 'Brit Iron' is commanding seriously stupid money these days so I was looking for something different. My thoughts turned back to the VFR. The engine is probably one of the best that Honda ever put into a road bike. After the problems they encountered with the original VF750, the engine in the VFR was over-engineered to a massive degree. The engine is generally regarded as being 'bullet proof'. Currently, they are extremely good value with good examples fetching less that two grand.

I trawled the interweb and eventually found what I was looking for in an advert in the 'Auto Trader'. It's a 4th generation VFR750FS from 1995, probably the best looking model of the VFRs, and I would get change out of 2 grand. It was in a dealers showroom in Swindon so I gave them a bell. The salesman gave what information I needed and was honest in his description. It had been through the hands of more than a few previous owners and had 67,000 miles on the clock, which shouldn't be a problem for this engine. It was offered with a short warranty and a full years MOT. Delivery was arranged, a payment made, and the bike was delivered to me early this afternoon. Only time will tell if I've bought a silk purse or a sow's ear. I did get off to a good start, however, as a nail was found in the rear tyre during the pre-delivery inspection. The punctured tyre has been replaced with a brand new Michelin 180/55 Pilot radial (Not exactly the correct size for the bike, it should be a 170/60 but I wasn't about to tell them to take it off.) That's a hundred and fifty quids worth of anyone's money. Fortunately, not mine!! There is a great video on YouTube that documents the history of the VFR (Vee Four Racing). If you're interested, you can view it HERE.

Friday, 8th October, 2021.

With the legalities completed the bike is now insured and taxed. Those very nice people at RH Insurance have agreed to add it to the five bikes I already have insured on my Classic Policy and it will only cost an additional £20 a year. I call that a 'result'.  I had to wait 24 hours for the insurance to appear on the Motor Insurers Database before I could tax it, however. Today, I rolled it out of the garage for a pre-ride check. I located the oil level dip-stick. It's full of reasonably clean oil. The tyre pressures were a bit below what's recommended (36psi, front and 40psi, rear) so I added some air. I've no idea where the radiator cap is and I wasn't about to start stripping off the body panels to find it. I'll ask Les, my Honda technician mate, in due course. I checked that all the electrics worked as they should and familiarised myself with the switches and buttons. I reset the trip odometer and also reset the LCD dashboard clock. It all looked in remarkably good order. There are some small blemishes on the paint work and a couple of minor dents in the tank but nothing of any consequence. Time to put some petrol in and take her out for a ride. There wasn't a lot of fuel in the tank and the low fuel level warning light on the dashboard was 'on'. Unfortunately, I failed to note the reading on the fuel gauge, but no matter. I emptied a 5 litre can of petrol into the tank but couldn't actually see the fuel level. The warning light had gone out and the fuel gauge now indicated over 3/4 of a tankful. Hmmm..... I dumped in another 10 litres. Now I could see the fuel level but the tank was by no means full. The tank holds 21 litres according to the specification. I'd put in 15 so it was at least 3/4 full now. The fuel gauge was hard up against the stop at the 'Full' end of the scale. Not a very accurate instrument. I'll make a note of that and get a replacement sender unit in due course. OK... time for a ride!!

I had to wait 24 hours for the insurance to appear on the Motor Insurers Database before I could tax it, however. Today, I rolled it out of the garage for a pre-ride check. I located the oil level dip-stick. It's full of reasonably clean oil. The tyre pressures were a bit below what's recommended (36psi, front and 40psi, rear) so I added some air. I've no idea where the radiator cap is and I wasn't about to start stripping off the body panels to find it. I'll ask Les, my Honda technician mate, in due course. I checked that all the electrics worked as they should and familiarised myself with the switches and buttons. I reset the trip odometer and also reset the LCD dashboard clock. It all looked in remarkably good order. There are some small blemishes on the paint work and a couple of minor dents in the tank but nothing of any consequence. Time to put some petrol in and take her out for a ride. There wasn't a lot of fuel in the tank and the low fuel level warning light on the dashboard was 'on'. Unfortunately, I failed to note the reading on the fuel gauge, but no matter. I emptied a 5 litre can of petrol into the tank but couldn't actually see the fuel level. The warning light had gone out and the fuel gauge now indicated over 3/4 of a tankful. Hmmm..... I dumped in another 10 litres. Now I could see the fuel level but the tank was by no means full. The tank holds 21 litres according to the specification. I'd put in 15 so it was at least 3/4 full now. The fuel gauge was hard up against the stop at the 'Full' end of the scale. Not a very accurate instrument. I'll make a note of that and get a replacement sender unit in due course. OK... time for a ride!!

First Impressions... were favourable. The bike felt comfortable as I tootled off down the road. Where I live in rural Lincolnshire, there is a network of minor country roads out by the Wash, stretching from Sutton Bridge in the east to Fosdyke in the west. I have developed a 'test circuit' of some 35 miles on these roads that I ride my bikes round. There are some 'twisties', some corners and some long straights (but no hills). Unfortunately, at this time of the year, the farm traffic lays an awful lot of mud onto the roads, which limited me a bit. On the whole, I was very happy with the way the bike performed. On Red Cow Drove, a 2 mile long straight with a slight curve in the middle, I managed to wind the throttle open in 4th gear... 'Kin 'Ell... It's fast!! Fortunately, the triple disc brakes are well up to the task and hauled the bike back down to something a little more comfortable. The run back down the A17 from Fosdyke was congested in both directions with lorries and huge tractors hauling trailers so I just stayed with the traffic and enjoyed the ride. Looking forward to the next outing.

Sunday, 17th October, 2021.

I didn't have to wait long for the next ride out. Yesterday was fine and reasonably warm so I headed to the local petrol station to fill the tank and reset the trip odometer. A precaution, as I don't trust the dashboard fuel gauge. A search on the internet suggested that 35 m.p.g was about average for these bikes. With a full tank, that equates to around a 150 mile range. I headed south... to The Two Wheel Centre in Harpenden to be precise, to meet up with Les, Nick and Sophie for a chat and a cup of tea. I called in to see my sister in St Ippolytes on the way as I hadn't seen her for a while and I wanted to show off my latest acquisition. As suspected, she wasn't overly enthusiastic. Older brother would be better occupied planting flowers and playing Scrabble rather than racing around the country on a 150m.p.h. motorcycle... Ho hum... Not going to happen! My younger niece told me I need a carer when she saw a photo of me up at High Neb in a howling gale a year or two ago. Heaven knows what she'll think of me when my sister tells her I've got ANOTHER motor bike. (My elder niece saw the same photo and posted a short note... "Old uncles rock!!")

Having had tea at the TWC, and having the tacit approval of Les, one of Honda's biggest fans, I headed to the nearest petrol station. I had around 130 miles on the clock and needed to fill up again. Surprisingly, it only took 10.57 litres (2.33 gallons) to fill the tank. That's about 56 m.p.g. Much better than I'd expected, but to be fair, I wasn't exactly racing it. I guess that figure will drop as I get familiar with the bike and start riding it harder. That will have to wait until next year, probably. There are one or two issues to sort out over the winter. The tank has five small dents in it but I've sourced an un-dented replacement of the correct colour on the internet. It also has a fuel gauge sender unit fitted so it may well sort out two problems. There is some repair work to do to the body panels at the rear end as it turns out that the rear light assembly is not secure. The fixing tabs have broken and need sorting out before I ride the bike again. Currently, the Bonneville in in the workshop but the work on that has been completed. I'll move that into the garage and bring the VFR into the workshop sometime in the not-too-distant future. That will give me all winter to sort out the wrinkles and give it a full service.

Second Impressions... It's quite hard work. With a full tank, the bike is a bit "top heavy" and tends to fall into corners if you let it. I found initially, I was too stiff, and riding it like my old AJS. Being a bit too careful, probably. By the time I'd got a hundred or so miles on the clock I'd loosened up a bit and riding it a bit harder into bends. Don't get me wrong... I wasn't exactly wearing out the knee sliders but I was definitely leaning it over further with more confidence. Les reckons that the limit will be me, not the bike. At the moment, about 250 miles is as far as I'd want to ride it in one day. By the time I got home, my hands and shoulder were aching significantly. Hmm...

Wednesday, 20th October, 2021.

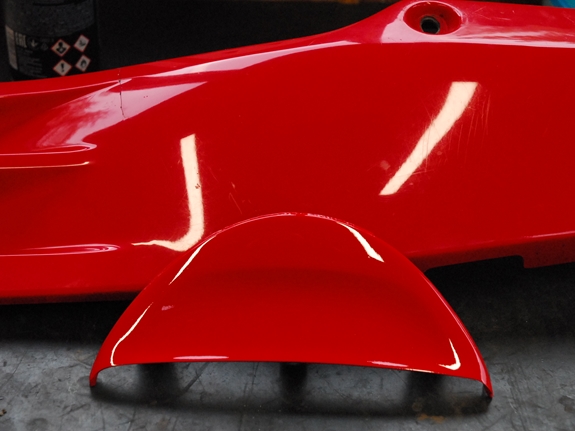

Something was bugging me... It was the cowl over the rear of the dual seat and the two grab handles that stuck up like a pair of horns. I had to do something about them. First off, a previous owner (hereafter referred to as the PO) had seen fit to adorn the cowl with a "Yoshimura" badge. I know not why, for it is a genuine Honda part. So that has to come off but first, I undid the two retaining bolts and took the cowl off completely. It's easier to work on it in the workshop. Fortunately, the adornment was only stuck on with a contact adhesive and it came off easily. The sides of the cowl had been seriously attacked with what looked like the PO's false teeth to create the cut-outs that cleared the two grab handles. Quite honestly, they were a mess. Much too big and two completely different shapes. It's unlikely that I will ever carry a pillion passenger, so the grab handles are superfluous. I have it on Les's authority that they can be refitted under the set and only brought out in the unlikely event of a passenger being carried, in which case, the cowl will have to come off anyway. With that in mind, I'll repair the cutouts and restore the cowl to how it was originally, without them. As someone once said... "We have the technology. We can re-build him (it)." To that end, I've ordered a small sheet of 2.5mm thick black ABS sheet, the same material as the cowl, and I'll cut out two patches and fix them in. That repair will be documented on a separate web page, once the repair has been successfully accomplished and I'll put a link to it at the bottom of this blog. It will, of course, then require repainting. Honda, in their wisdom, affix a label under the seat stating the colour and the paint code... In this case "Color R-158P" and "Code R158D". I've ordered an aerosol of colour base coat and clear lacquer top coat. Hopefully, I'll be able to restore the cowl correctly. The more "eagle eyed" amongst you will no doubt have noticed that the front fixing point is also broken. I'll attempt a repair on that as well.

I've not been idle at the computer, either. Fowlers website has full parts lists for Honda bikes. Very useful when ordering spare parts from them or that very nice Mr David Silver, purveyor of spare parts for aging Hondas. I've ordered some stuff that I know I'll need to service the VFR... oil, filters, plugs, cam cover gaskets etc. It's not cheap!! It came to over two hundred of our finest British quids, but as I have no service history for the bike and it has done over 67,000 miles, we (me and Les) will be doing a major service, including the valve shims.

Friday, 22nd October, 2021.

While I was waiting for some stuff I'd ordered to arrive, I got the VFR into the workshop, and with the help of a local friend, Jonny Benton, we got it onto the workbench and up on its centre stand. That was yesterday... Today, I stripped off the seat, side and rear fairing panels and rear light assembly. As mentioned earlier, the rear light was loose and now I know why, but I'll come to that later. There have been more than a few POs and some of them weren't as conscientious as they might have been. A number of the fairing fixings have been brutalised. The two main fixings for the side panels had both seen better days. The left hand captive M8 nut had been stripped at some point and repaired. That was OK and was serviceable. The right hand one was also stripped had had been bodged with a non-standard bolt. That I've repaired by brazing a new M8 threaded insert into the frame. I've ordered new bolts and rubber mountings for both side panels. The rear light was loose because one side of the lower plastic cowl had completely broken away. New parts like that are no longer available from Honda but I have managed to find a good one on eBay for £13. It's the wrong colour, but hopefully, I'll have enough in the aerosols to paint that as well as the other parts that I'm going to repair. A number of fixing screws for the panels around the rear light weren't doing their job properly either. I've ordered all new fixings for those panels as well. The left hand side panel has a nasty crack in it but hopefully, I'll be able to repair that too. There are some second hand ones on the internet but I'll have a go at repairing this one before I spend a lot of hard earned pension on replacements.

Sunday, 24th October, 2021.

I've not had a lot of experience at repairing plastic fairing panels. The only other fully faired bike I've owned was a 1986 Honda VF1000F-2 Bol D'Or that had 120,000 miles on the clock. The fairing panels on that were so beat-up that they were all held together with cable ties. With that in mind, I decided to test my skills on a small panel first, probably the smallest panel on the bike, the rear light upper cowl. That had a small crack in it adjacent to the central fixing lug. I'd acquired a cheap electric tool for repairing plastic panels from a well known internet market place, possibly located in Brazil. It passes an electric current through a steel "wavy staple" to heat it up and melt the plastic, leaving the staple embedded across the crack. Nothing venture, nothing gained so I gave it a go.

Hmm... I have to say that for a first attempt, that went reasonably well. The electrikery thingy did what it said on the box and there is now a wavy steel staple embedded in the plastic, at both ends of the crack. That holds it together securely but it doesn't actually "mend" it, if you see what I mean. According to the writing moulded onto the underside of the panel, the material is "ABS", which, if you really want to know, is the abbreviation for Acrylonitrile Butadiene Styrene. I knew the two years I spent at college studying Organic Chemistry wouldn't be wasted, because I know that it's the same stuff that plastic waste pipes and fittings are made of... and you can glue that stuff together, right? Right!! I cleaned the back surface and applied a liberal coating of waste pipe solvent cement to the crack, then left it for 24 hours. It's now really solid and should last another 26 years.

The paint I ordered from Advanced Paints has arrived. One 400ml aerosol of red base coat and one 400ml aerosol of clear top coat. Now there might just be a problem with that. When you check the Honda colour code on-line, it comes up as metallic red. I didn't think that my bike had metallic paint and Honda's name for the colour, "Pure Red", did nothing to make me believe otherwise; particularly as the two other colours that Honda painted the VFR in 1995 had "metallic" in the name... "Mute Black Metallic" and "Starlight Silver Metallic". I reasoned that if it was metallic paint, it would have been called "Pure Red Metallic". Anyway, when I spoke to the guy at Advanced Paint, he told me that there were two different paints with the same Honda code, a solid red and a metallic red. I ordered the solid red paint. I hope I've made the right choice. That's another reason I've chosen to start with the smallest panel on the bike. There will be less to correct if I've made the wrong choice.

Wednesday, 27th October, 2021.

Wednesday, 27th October, 2021.

Good news and bad news... Good news first. I was very happy with the repair to the little cowl panel. I'd ground out the crack on the face side, filled it with a flexible epoxy filler, and then rubbed it down with 320 grit waterproof sanding paper. I gave it 5 coats of hi-build filler primer and left it for 24 hours. That was flattened off with 1200 grit paper and then had 5 coats of red base coat. Again, left for 24 hours and then that, too was flatted with 1200 grit paper before being given just one coat of gloss clear lacquer. At that point I stopped but even with just one coat of lacquer and no polishing, I was impressed with the finish.

Now the bad news... the colour match with the original was a bit off. Not easy to see in the photo, but the new paint was a little more 'orange' than the original paint work. In fairness, that may well be down to me. When I bought the filler-primer, I didn't realise it was yellow. That may well have contributed to the slightly orange hue of the finished job. I've also done a bit more on-line research and it turns out that I may well have ordered the wrong base coat from Advance Paints. It seems that the general opinion on the VFR chat forums is that the red should be the pearl metallic. Ho hum... Anyway, I've now ordered a couple of aerosol tins of white primer and a tin of the pearl metallic red from Advance Paints. In due course, I'll sand the cowl back to the plastic, apply white primer and the pearl base coat. We'll see if that is a better match!! Win some, loose some!!

Friday, 29th October, 2021.

The replacement rear light lower cowl that I sourced on the interweb turned up a couple of days ago. It's the wrong colour and has a couple of light scuff marks but nothing that I can't correct. At least this one isn't broken and should go a long way to securing the rear light correctly. It was a bit on the grubby side so a quick turn in the parts washer (my kitchen dishwasher) and it was sparkling. The aerosols of white primer and red pearl base coat have also arrived so I'll be good to go when I come back from a fishing holiday in Norfolk.

Friday, 12th November, 2021.

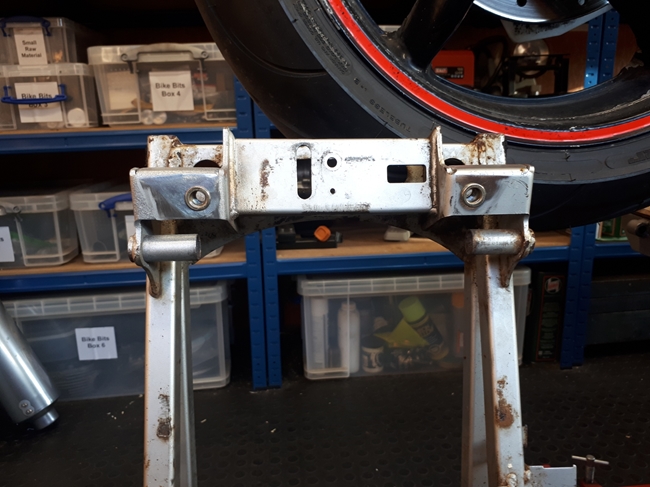

After a reasonably successful week's pike fishing on the River Bure, it was time to get back to the VFR. Quite a bit has happened since my last entry on this blog. First off, I wasn't altogether happy with the repair I made to the rear sub-frame thread. The paint on the sub-frame, or lack of it, was also giving me some concern. The metalwork was pretty rusty on the underside where the paint had fallen off over the years. I decided to take it off, put two new threaded inserts in and get the frame powder coated. In the great scheme of things, it wasn't all that difficult. There were a few electrical bits and pieces to take off but they were mostly held in rubber mountings and could be removed from the frame without disconnecting them. That just left the pillion footrest hangers and exhaust silencer mounting. With those off, the four mounting bolts at the front end were removed and the sub-frame was slid out backwards. The rear threaded fixings were repaired properly and the frame is now with Breckland Finishing in Thetford to be media blasted, then powder coated with a chromate primer and a silver top coat.

In the great scheme of things, it wasn't all that difficult. There were a few electrical bits and pieces to take off but they were mostly held in rubber mountings and could be removed from the frame without disconnecting them. That just left the pillion footrest hangers and exhaust silencer mounting. With those off, the four mounting bolts at the front end were removed and the sub-frame was slid out backwards. The rear threaded fixings were repaired properly and the frame is now with Breckland Finishing in Thetford to be media blasted, then powder coated with a chromate primer and a silver top coat.

While the rear sub-frame was away, there were a few other things I wanted to do. The paint on the rear wheel didn't look too bright so the wheel came off for a closer inspection. 'Kin 'ell, those wheel nuts were tight... much tighter than they should have been and I had to get a bit inventive to get them undone. Up close, the paint on the wheel was not good. It had bubbled up and lifted allowing the aluminium underneath to corrode... badly. That was a bit of a bummer. While the corrosion could be removed by media blasting, powder coating wouldn't disguise the pitted aluminium and it's structural integrity may well have been compromised. A quick search on the interweb revealed that there were a number of second hand wheels available, all in better condition than mine. I will be driving down to Bury St. Edmunds this evening to pick up a replacement. While the wheel was off, I had a look at the rear brake calliper. I know from experience, that single sided, sliding callipers could, if not looked after, seize up and no longer slide as they should. Fortunately, the calliper seemed to be in perfect condition. The pads were more than half worn so for the sake of a few quid, a set of new EBC brake pads were slipped in. I've also sourced a new set of wheel nuts to replace the very rusty ones fitted. To buy a set specifically for a VFR750 would cost the best part of £38. However, Honda in their wisdom, used the same nuts on their cars and a set of four chrome nuts, listed for a Honda Civic, only cost £8. That's what I call a result!

Sunday, 14th November, 2021.

I collected the replacement rear wheel and I'm happy to say that it is much better condition that the one that was fitted to my bike. I've taken the front wheel off and I'll take them both over to Central Wheel Components in Coleshill. They will media blast the old paint off and powder coat them. I had to remove the front wheel bearings as any grease they contain may leak out during the powder coating process and ruin the powder coating. I've already obtained a new set of bearings and grease seals to put back in due course. Like in the rear brake, the brake pads in the front callipers were more than half worn, so they will be replaced, too.

The rear cowl mouldings have now been re-sprayed with the pearl metallic paint and look good. The colour match isn't perfect but I can live with that. It's better now that I used a white primer undercoat.

Tuesday, 16th November, 2021.

Tuesday, 16th November, 2021.

Yesterday, I took the 'new' rear wheel and the front wheel to Gildo's Motorcycle Centre in Wisbech. Adam (good bloke) kindly agreed to take off, and dispose of, the old tyres for me. Splendid... tomorrow, I'll be taking them both to Central Wheel Components to be stripped of the old paint and powder coated. I will no doubt be meeting up with a couple of mates in The George and Dragon in Stoke Golding (the 'Brewery Tap' for the Church End Brewery) to enjoy a pint of lunch.

Having sorted out the plastic rear cowl panels, it was time to have a look at the left hand side panel. There was a nasty split in the plastic which needed to be sorted before it became any worse. I did try the heated staple method but unfortunately, the panel wasn't thick enough and the staple went straight though. Time for Plan "B". I cut up a number of pieces of 2mm thick black ABS sheet. Having removed the paint from around the split on the inside of the panel, the pieces of ABS were cemented over the split with an acetone based solvent adhesive. I did think about grinding out split on the outside of the panel and filling it with a flexible filler, but I don't think the paint match would be good enough and decided to just leave the split as it is. I feel it will be less visible that way. I'll keep my eyes open for a second hand panel. They do come up on eBay from time to time.

Wednesday, 1st December, 2021.

I've had calls from Richard at Breckland Finishing and from Kathy at CWC to say that my rear sub-frame and the wheels are ready for collection. With that in mind, I'll be going west to Coleshill tomorrow and south to Thetford on Friday to pick the stuff up. That means I can get on with putting the bike back together at the weekend.

The front brake lines had all been replaced with stainless steel braided hoses, a good upgrade, but the rear brake hose was the original, 26 year old rubber item. These have a limited lifespan and it was time that this was changed for stainless steel also. It just so happened that this decision coincided with "Black Friday". That's another stupid American import that the great unwashed seemed to have taken on board. That doesn't mean, however, that I couldn't take advantage of it. HEL, one of the premier suppliers for all things hydraulic, were having a Black Friday Sale. I managed to buy a new, custom made, braided stainless steel rear brake hose with new banjo bolts and copper washers for just 22 of our fine British quids. That's a result in my book! That has now been fitted. It will, of course, meant that the rear brake will need 'bleeding', but that will have to wait until I've obtained some new DOT4 fluid. I did find some in the workshop but it was only half a bottle and was at least 5 years old. That was disposed of in an approved manner.

It was about this time that I started thinking about the exhaust system. I had to remove the silencer in order to take off the rear sub-frame and was surprised just how heavy it was. It weighs in at around 13.1/2 pounds. It also rattled significantly when it was shaken. To me, that means that something inside has broken loose. I also noticed that it wasn't connected to the collector box that's mounted under the engine, in the correct manner. The outlet pipe from the collector box has a flange on it. The link pipe from the silencer should have a similar flange and the two flanges should be held together, with a 'doughnut' type gasket between them, by a two piece clamp. On this bike, the gasket and the clamp were missing completely. The flared end of the link pipe had been removed and the two pieces held together with a jubilee type clip.

An enquiry on the VFR Owners Facebook site gave me some of the information I needed. First off, the down pipes and collector box are made from stainless steel. This means that they are an 'after market' item, presumably fitted as the original mild steel Honda pipes had rusted. Unfortunately, I have no idea what company made them. Second... Genuine new Honda pipe clamps and gaskets are no longer available. However, pattern doughnut gaskets are available but are apparently of dubious quality. I did manage to find a second hand original Honda clamp for the pipe flanges on eBay. It's a bit on the manky side and pretty rusty but it may be serviceable. With that in mind, I've bought a new silencer and link pipe from "Black Widow Exhausts". That arrived a couple of days ago.

Offering up the new stainless link pipe to the collector box outlet pipe, it was patently obvious that the second hand clamp would not hold the two pipes together with the pattern gasket in place. The gasket was much too big and the respective flanges were too far apart. Time for a re-think. Back on the VFR owners Facebook site, a couple of people had mentioned using a 2" stainless V-Band clamp usually used on car turbo-charger pipe work. They are readily available only cost a few quid so I ordered one. It certainly looks better than the rusty original one, but it doesn't address the problem with the doughnut gasket. Offering up the link pipe without a gasket in place, as in the photo, the clamp works well. I think that if I create my own gasket from glass fibre rope used to seal wood burner stove doors, and a liberal application of exhaust pipe sealant, I might just get away with it. I've ordered some 6mm and some 8mm glass rope. Time will tell if I'm right, or barking up the completely wrong tree! I'll have to wait until the rear sub-frame is back in place before I can fit the link pipe to the silencer and offer up the complete system.

Friday, 3rd December, 2021.

I've collected the sub-frame from Breckland Finishing and the wheels from CWC and I have to say, both companies have done a great job. I dropped the rear wheel off at Gildo's in Wisbech, and Adam has swapped the new rear tyre from the old wheel onto the newly powder coated rim. Back in the workshop, the new bearings and grease seals have been installed into the front wheel. The tool I made worked beautifully and the installation was totally hassle free. The threads for the brake disc screws were cleaned out and all the old Loctite on the screws cleaned off. The discs were then mounted back onto the wheel in exactly the same position that they were in before I removed them. This I know because I had marked them, and the wheel, with a centre punch before I took them off. Blue Loctite was applied to the screws before they were tightened to 10 lbs/ft with a torque wrench.

Saturday, 4th December, 2021.

First job today was to put the front wheel back in, but before I could do that, I had to install the new front brake pads. Easy enough with the wheel out. Going back a stage... to take the front wheel out, the front of the bike has to be supported. The workshop manual says to jack it up underneath the exhaust pipes. To me, that didn't sound like a good way to safely support the not inconsiderable weight of the bike. I'd tackle it from the other direction and hang it from a "sky hook". By sheer good fortune, the handlebars were directly below the main roof support cross member so I screwed up a couple of stainless steel marine fittings that I just had "kicking about". I raised the workbench a few inches up from the safety bar, put a webbing sling around the bars and used a ratchet strap to take up the slack, then lowered the bench back down. The front wheel was now no longer supporting the bike and was easily removed, after taking off the front mudguard.

First job today was to put the front wheel back in, but before I could do that, I had to install the new front brake pads. Easy enough with the wheel out. Going back a stage... to take the front wheel out, the front of the bike has to be supported. The workshop manual says to jack it up underneath the exhaust pipes. To me, that didn't sound like a good way to safely support the not inconsiderable weight of the bike. I'd tackle it from the other direction and hang it from a "sky hook". By sheer good fortune, the handlebars were directly below the main roof support cross member so I screwed up a couple of stainless steel marine fittings that I just had "kicking about". I raised the workbench a few inches up from the safety bar, put a webbing sling around the bars and used a ratchet strap to take up the slack, then lowered the bench back down. The front wheel was now no longer supporting the bike and was easily removed, after taking off the front mudguard.

With the front wheel and mudguard back in place, the bike was lowered back down and the ratchet strap removed. Next job was the rear sub-frame. Before I started, all the threaded attachment points were cleaned out with a tap and lubricated. It's surprising how much blasting media gets trapped in the threads when things are prepared for powder coating. It can cause screws to jam in the holes and possibly cause threads to strip. That done, the frame slipped back into place and was bolted up to the correct torque, as specified in the Service Manual. The various bits and pieces that were attached to the sub-frame were put back and the electrics connected up. I really hope that all the electrics work, but I wont know until the battery finally goes back in.

The final job today was to rebuild and put back the right side pillion footrest hanger. The footrests themselves are pivoted and have a spring loaded detent ball to keep them either up or down. When I took them off, the detent balls were jammed solid with a mixture of rust and aluminium corrosion. They have been replaced with new components and now work as they were intended. I won't say it was easy... I lost count of the number of times that bloody steel ball was fired across the workshop by the inordinately strong spring before I finally got it installed. Ho hum...

Sunday, 5th December, 2021.

So... another day and another hour or two in the workshop. First job today was reassembling the left side pillion footrest hanger. This one has the seat lock attached to it. I had removed the lock assembly as it was very rusty and needed cleaning up. Now I had to put it back. It was originally attached with security "shear bolts". The sort that has a weak spot that is designed to break at a certain torque and the hex head snaps off, meaning that there is nothing to get hold of to undo them. With the hanger on the bench, a fine cutting disc on the Dremel sorted that out. New Honda shear bolts are no longer available, so I've reattached the lock assembly with stainless security Torx screws. I've also sourced a good, second hand, seat lock cable to replace the old, frayed one that I took off. I learned my lesson yesterday and the spring loaded detent ball went in without a problem this time.

So... another day and another hour or two in the workshop. First job today was reassembling the left side pillion footrest hanger. This one has the seat lock attached to it. I had removed the lock assembly as it was very rusty and needed cleaning up. Now I had to put it back. It was originally attached with security "shear bolts". The sort that has a weak spot that is designed to break at a certain torque and the hex head snaps off, meaning that there is nothing to get hold of to undo them. With the hanger on the bench, a fine cutting disc on the Dremel sorted that out. New Honda shear bolts are no longer available, so I've reattached the lock assembly with stainless security Torx screws. I've also sourced a good, second hand, seat lock cable to replace the old, frayed one that I took off. I learned my lesson yesterday and the spring loaded detent ball went in without a problem this time.

As I'd fitted a new rear brake hose, I now had to bleed the air out. I have a vacuum brake bleeding tool kit which makes the job very easy and I'd bought a new bottle of DOT4 fluid. With that accomplished, the rear wheel was bolted back on with the new chrome wheel nuts that I obtained earlier. The 80 lbs/ft of torque needed to fully tighten them meant I had to use a ratchet strap around a spoke and the work bench to stop the wheel turning. No big deal.

Last job today was to offer up the new exhaust silencer and link pipe. Much to my surprise, it seems to fit reasonably well. I made a gasket out of a few coils of 8mm diameter fibre glass rope. That compacted down really well and the V-band Turbo clamp pulled the two flanges together to make what I hope is a gas-tight joint. The silencer is absolutely "straight through" so there isn't going to be a lot of back pressure to force exhaust gas out of the pipe joint. I think it looks pretty smart, too.

Monday, 6th December, 2021.

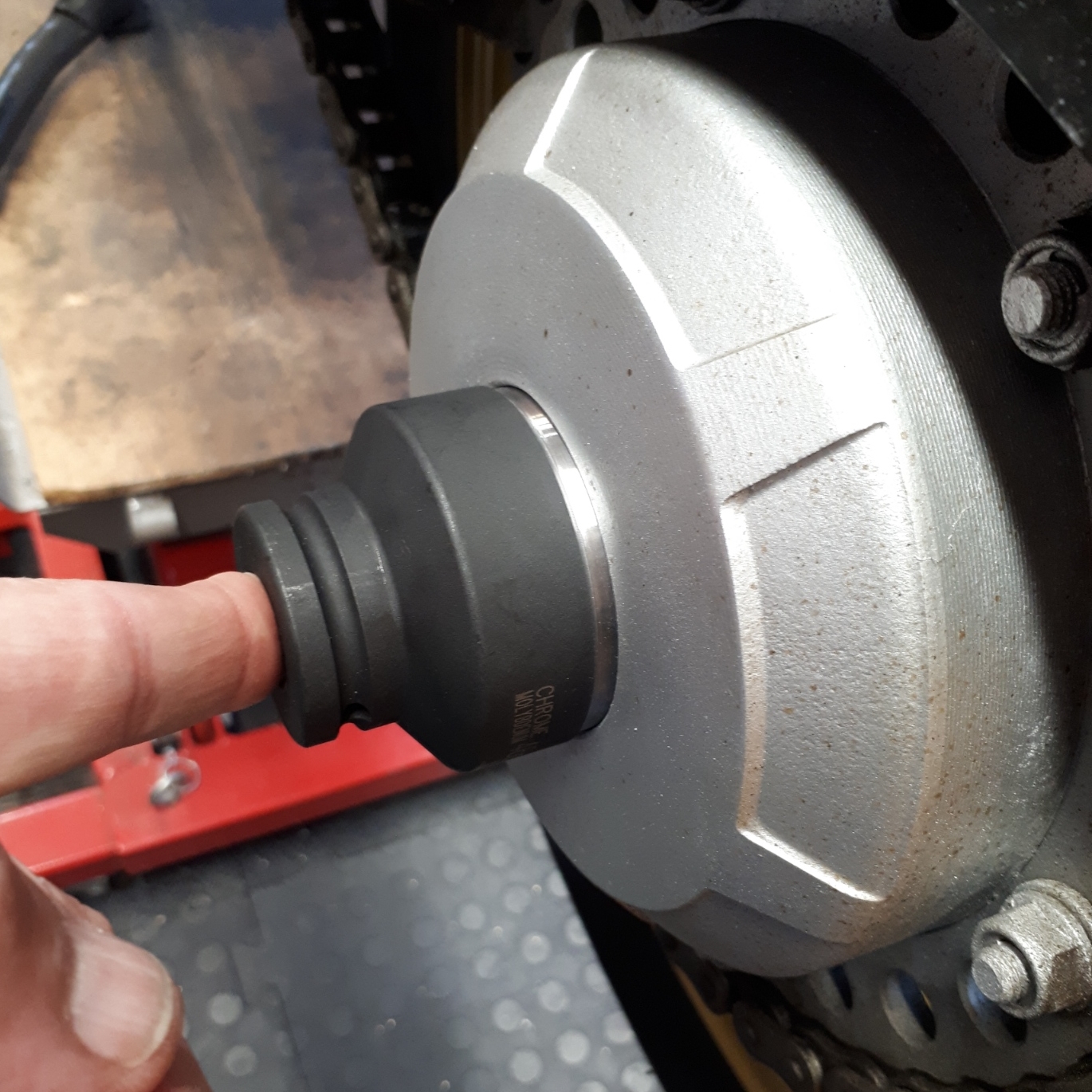

It was while I was chatting to a couple of old biker mates a few days ago that one of them mentioned the single sided swinging arm on the VFR. If I ever needed to remove the hub from the arm, I would need a 46mm A/F socket spanner to undo the big nut that holds it all together. I do have a number of big sockets but I didn't have one that was 46mm A/F so I bought one. Better to have a tool and never need it than to need one and not have it. The nut is quite thin and partially inset into the hub casting. The socket O/D was just a little too large to fit into the casting recess so I had to put it up in the lathe and turn a couple of millimetres off. Now it fits and will be in the toolbox should I ever need it.

It was while I was chatting to a couple of old biker mates a few days ago that one of them mentioned the single sided swinging arm on the VFR. If I ever needed to remove the hub from the arm, I would need a 46mm A/F socket spanner to undo the big nut that holds it all together. I do have a number of big sockets but I didn't have one that was 46mm A/F so I bought one. Better to have a tool and never need it than to need one and not have it. The nut is quite thin and partially inset into the hub casting. The socket O/D was just a little too large to fit into the casting recess so I had to put it up in the lathe and turn a couple of millimetres off. Now it fits and will be in the toolbox should I ever need it.

With the sub-frame and exhaust fitted, the rear light cowl and side panels were re-assembled. Not having done that before, I wasn't sure what order the bits had to be put together. Actually it was reasonable intuitive and there were no real problems. It all had to be re-assembled on the bench and fitted onto the bike in one piece, with the exception of the cowl over the pillion seat which was fitted once all the other parts were in place. The panels were all fixed with new stainless flange screws and then fitted over the sub-frame and secured with new Honda OEM fittings. It looks much better without the two "horns" sticking up at the back. The paint isn't an exact match... I didn't think it would be as the unpainted panels have faded over the 26 years the bike has been on the road. It is, however, acceptable and that's all the painting I'm going to do for the time being.

With all the bodywork in place and the electrics connected up, I put the battery back. It had been on a maintenance charger since I took it off. There should have been a rubber strap over the battery to secure it but that was missing. They are available it seems, and will be added to my ever growing shopping list. I turned on the ignition and all the dash-board indicator lights lit up as they should. Having had to disconnect some of the electrical stuff to remove the rear sub-frame, I wasn't absolutely sure that it would all work when I reconnected it. Fortunately it did. Time to fire it up... I hit the starter and it cranked away for a few, long, seconds before it fired up and ran. I had a voltmeter connected across the battery and while it dropped to 10.5 volts while turning the engine over, with the engine running, it was showing 14.8 volts. That was a good indication that the rectifier / regulator was doing it's job. They are a weak point on these bikes apparently, and prone to failure, usually taking the battery out with them. The one fitted is an after-market replacement, so it's good to know that it's working. The exhaust note was suitably muted with the Black Widow "dB killer" in place. It would have been silly not to see what it sounded like with the baffle removed, so I took it out. The exhaust note was considerable sharper and a bit louder. If I was a hooligan, I might be tempted to leave it out but as I'm not, I put it back in. No need to draw more attention to yourself than is necessary.

Saturday, 11th December, 2021.

Having put the rear fairing panels back on the bike, I took them all off again. This time, in preparation for the full service that I intend giving it. The bike has 67,000 miles on the clock and has no service history so it is something than needs doing. The rear panels were easy as I'd only just had them off but the front ones were a little more tricky. Some of the Dzus quarter turn fixings had been replaced with non-originals... Not totally unexpected on a 26 years old machine. A couple were very rusty and had to be persuaded to come out. Some of the spring clips that the Dzus screws lock into were extremely rusty and on the verge of falling apart. I thought it would be nice to replace them... Then I looked up the price on the David Silver web-site. To replace the 10 screws and 10 spring clips would cost me £123.60 plus postage. That wasn't going to happen; time to trawl the interweb. I found the exact Dzus fixings that Honda fitted, sold as a set of 10 screws, washers and spring clips for just £21.95 post included. That's a result!

With the fairing removed, I could start with the simple stuff. The coolant was drained as I will have to move the radiator at least, if not remove it completely, in order to get access to the front cylinder camshaft cover. The oil was also drained as I have no idea how long it's been in the engine. Not a moment too soon if the condition of the oil filter can was anything to go by. It was very rusty and reluctant to unscrew but it did succumb in the end. The right side engine case is in a right mucky state. It was originally painted black but a lot of the paint has been lost and the aluminium is quite badly corroded. It has to stay in place for the moment as it has the reference mark on it that I will need when I check and if necessary, adjust, the valve clearances. Once that has been completed, I'll take the cover off, get it vapour blasted and I'll give it a fresh coat of black, silk finish, paint. The air box had to come off but that's no big deal as I have a new air filter to go back anyway. I stuffed the four carburettor venturi with kitchen towel to stop anything dropping into the engine.

The right side engine case is in a right mucky state. It was originally painted black but a lot of the paint has been lost and the aluminium is quite badly corroded. It has to stay in place for the moment as it has the reference mark on it that I will need when I check and if necessary, adjust, the valve clearances. Once that has been completed, I'll take the cover off, get it vapour blasted and I'll give it a fresh coat of black, silk finish, paint. The air box had to come off but that's no big deal as I have a new air filter to go back anyway. I stuffed the four carburettor venturi with kitchen towel to stop anything dropping into the engine.

Monday, 13th December, 2021.

Things took a definite turn for the worse this morning. According to the Service Manual, the coolant radiator could be pivoted forward on the top fixings far enough to allow access to the front cylinder camshaft cover. Unfortunately, it didn't quite go as planned. The radiator bottom fixing was so badly corroded that it broke away from the radiator frame. That was a bit of a bummer and meant that I had to completely remove the radiator. That wasn't difficult but I did have to move some other bits out of the way. Once it was out and on the bench, I could see the extent of the corrosion. It was pretty bad. So much so that there was no way that the radiator was going back on the bike. It would be a disaster waiting to happen. I'm surprised that it actually held coolant at all. The internet is great for finding things you need and I needed a replacement radiator. There are no new, genuine Honda radiators available but there are new replacement items, manufactured in Eastern Europe and, of course, China. These were retailing for around £150. There were also a number of second hand original parts and I found one in excellent condition from a vendor in Germany. That is now on it's way to me for £70, including carriage.

I'm surprised that it actually held coolant at all. The internet is great for finding things you need and I needed a replacement radiator. There are no new, genuine Honda radiators available but there are new replacement items, manufactured in Eastern Europe and, of course, China. These were retailing for around £150. There were also a number of second hand original parts and I found one in excellent condition from a vendor in Germany. That is now on it's way to me for £70, including carriage.

The radiator has an electric fan attached to it and this looked pretty rusty, too. Electrically, the fan works perfectly, which is good news. The frame can be cleaned up and painted to make it serviceable. The hoses look to be in good condition and I won't replace them, but I may replace the "Jubilee" type clips as they were a bit rusty.

I needed to spend more of my hard earned pension on some new equipment. Amongst all my tools, there was not one that I could use to unscrew and remove the spark plugs. They are tiny 10mm plugs with a 16mm A/F hexagon and are deep down in a tube in the cylinder head. There was a plug spanner included in the original Honda tool kit but that had long since disappeared. There were a few options available from tool suppliers on the internet. It has always been my thought that buying cheap tools is usually a false economy, so I've bought one of the better ones available. A 3/8" square drive, chrome vanadium plug socket spanner that is long enough to reach the deeply set plugs with ease. I needed another set of metric feeler gauges and I've also bought a 0-25mm metric micrometer.

Wednesday, 15th December, 2021.

Checking the valve clearances was on the list today. The new plug spanner worked perfectly and the four plugs were unscrewed and removed. They weren't as tight as I'd expected, barely more than finger tight, and with signs of oil having been pushed up the thread. Hmm... The camshaft covers on both banks of cylinders were removed. I have new rubber gaskets and bolt seals for when they go back. They were dirty and lightly corroded on the outside but everything under the covers looked to be in great condition. There was no build up of oily sludge, and the cams showed no sign of any wear. The lobes were unscored. That's very good news. Time to check the clearances. The clearance on the inlet valves should be 0.005" - 0.007" and the exhaust valves should be 0.009" - 0.011". On three of the cylinders (1, 3 & 4) all the valves were within tolerance and needed no adjustment. On cylinder 2, however, the exhaust valve clearances were OK, but the two inlet valves were just a little tight. With a clearance of 0.0045", they were just below the lower limit so they would need adjusting.

Checking the valve clearances was on the list today. The new plug spanner worked perfectly and the four plugs were unscrewed and removed. They weren't as tight as I'd expected, barely more than finger tight, and with signs of oil having been pushed up the thread. Hmm... The camshaft covers on both banks of cylinders were removed. I have new rubber gaskets and bolt seals for when they go back. They were dirty and lightly corroded on the outside but everything under the covers looked to be in great condition. There was no build up of oily sludge, and the cams showed no sign of any wear. The lobes were unscored. That's very good news. Time to check the clearances. The clearance on the inlet valves should be 0.005" - 0.007" and the exhaust valves should be 0.009" - 0.011". On three of the cylinders (1, 3 & 4) all the valves were within tolerance and needed no adjustment. On cylinder 2, however, the exhaust valve clearances were OK, but the two inlet valves were just a little tight. With a clearance of 0.0045", they were just below the lower limit so they would need adjusting.

The adjustment is made by changing the shim discs that are located on top of the valve stem, under the cam follower buckets. Putting in a thinner shim to increase the clearance or a thicker one to reduce it. To do that, the camshaft has to be removed. Not a difficult job, but it does require care and concentration.  The camshaft is held in place by two bearing caps and eight M6 bolts. Be aware... there are two different length bolts used. With the engine set at TDC on the compression stroke of cylinder 2, the eight bolts can be undone, following the sequence and procedure in the Service Manual. Now is the time for the care and concentration. The cam follower buckets can be lifted up and out of the cylinder head. You can't get a hold of them so I used a magnet to gently lift them up, making sure that the shim doesn't drop out and fall down the side of the valve spring. Fortunately, the shims remained stuck in the oil on the underside of the cam follows. The shims have their thickness etched onto one side. The shims installed both had "202" etched onto them, that's 2.02mm or 0.0795". When I checked them with a micrometer, they measured 0.0798" which is pretty close, just 3/10's of a thou different. I had a full selection of shims to choose from in 0.05mm (0.0019") increments. The nearest I had was "200" which measured 0.0790" with my micrometer. Replacing the existing shims with those would only just take the clearance inside the bottom limit, so I replaced them with "195". The shims sit in recesses in the valve spring cap, but I again had to be careful not to drop them. Replacing the camshaft is the reverse of removing it, but make sure the the timing marks line up and tighten the bearing cap bolts sequentially and evenly. I turned the engine over a couple of times by hand to make sure everything rotated and then checked those two valves again. They measured 0.006" and 0.007". Perfect!!

The camshaft is held in place by two bearing caps and eight M6 bolts. Be aware... there are two different length bolts used. With the engine set at TDC on the compression stroke of cylinder 2, the eight bolts can be undone, following the sequence and procedure in the Service Manual. Now is the time for the care and concentration. The cam follower buckets can be lifted up and out of the cylinder head. You can't get a hold of them so I used a magnet to gently lift them up, making sure that the shim doesn't drop out and fall down the side of the valve spring. Fortunately, the shims remained stuck in the oil on the underside of the cam follows. The shims have their thickness etched onto one side. The shims installed both had "202" etched onto them, that's 2.02mm or 0.0795". When I checked them with a micrometer, they measured 0.0798" which is pretty close, just 3/10's of a thou different. I had a full selection of shims to choose from in 0.05mm (0.0019") increments. The nearest I had was "200" which measured 0.0790" with my micrometer. Replacing the existing shims with those would only just take the clearance inside the bottom limit, so I replaced them with "195". The shims sit in recesses in the valve spring cap, but I again had to be careful not to drop them. Replacing the camshaft is the reverse of removing it, but make sure the the timing marks line up and tighten the bearing cap bolts sequentially and evenly. I turned the engine over a couple of times by hand to make sure everything rotated and then checked those two valves again. They measured 0.006" and 0.007". Perfect!!

Thursday, 16th December, 2021.

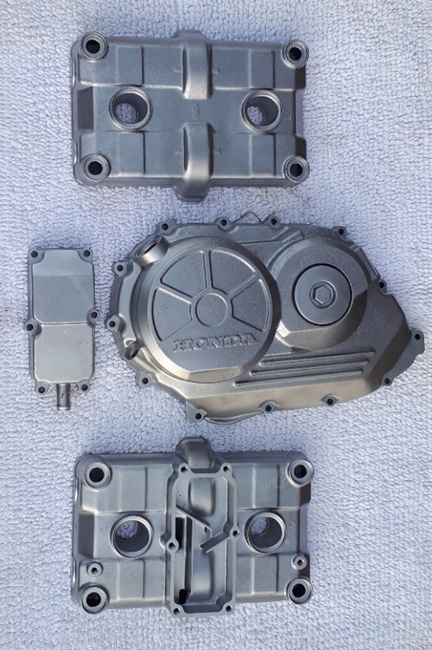

I've been in touch with Simon Collins at "Bike-Aquablasting". Next Tuesday, I'll be taking the two camshaft covers and the right side engine / clutch cover to be vapour blasted to get rid of all the old paint and corrosion. I'll give them a new coat of silk black high temperature paint. Hopefully, that will inhibit any further corrosion of the aluminium.

The camshaft covers are just a bit grubby. There is some light surface corrosion but it really isn't that bad. A coat of black paint will set them off, not that they're particularly visible under all the bodywork but is will stop any further corrosion. The engine cover is a different story. That was painted originally but over the years, the paint had been lost and the aluminium has corroded quite badly. I'll see what it's like when it comes back from vapour blasting. If it's still serviceable, I'll paint it and put it back. If not, I'll look at sourcing a replacement. There are one or two advertised for sale in the UK and Europe.

Monday, 20th December, 2021.

The replacement radiator that I'd bought from a guy in Germany turned up this morning. It certainly looks ok with no obvious signs of leakage. I'll take the temperature switch out and test it. I also have the switch from the old radiator. Hopefully at least one of them switches at the correct temperature... 100°C. I'll test them in a pan of salt water which should boil just above that temperature. I know the fan works as I had that running on the bench a few days ago. I've wire brushed all the loose rust and paint from the fan mounting shroud and given it a couple of coats of Hammerite smooth black paint. That's tidied it up a bit and made it look a little more presentable.

The replacement radiator that I'd bought from a guy in Germany turned up this morning. It certainly looks ok with no obvious signs of leakage. I'll take the temperature switch out and test it. I also have the switch from the old radiator. Hopefully at least one of them switches at the correct temperature... 100°C. I'll test them in a pan of salt water which should boil just above that temperature. I know the fan works as I had that running on the bench a few days ago. I've wire brushed all the loose rust and paint from the fan mounting shroud and given it a couple of coats of Hammerite smooth black paint. That's tidied it up a bit and made it look a little more presentable.

A LITTLE LATER.... I checked the operation of both coolant temperature switches and happily, they both switched on after being immersed in boiling salt water for about 20 seconds. That's good news, I now have a spare. One of them has been screwed back into the new radiator with a new sealing "O" ring and just a smidgin of grey ThreeBond sealer on the thread. I really don't want to have to take the radiator out again to cure a leak around the switch. The fan has been mounted back into the shroud and secured with new stainless flange nuts. That assembly has also been put onto the radiator, again with new stainless flange screws. The plastic mesh shield has been cleaned and clipped back onto the front of the radiator. It's now ready to be put back onto the bike, once the camshaft covers have been reinstalled. That, however, will have to wait until I've had them vapour blasted.

Wednesday, 22th December, 2021.

I took the covers up to Simon at "Bike-Aquablasting" yesterday and left them with him while I went for a pint of lunch and a sandwich at The George & Dragon in Stoke Golding. An hour and a half later Simon 'phoned to say that the job was a good 'un and I could collect them when I was ready. I have to say that the job was indeed a good 'un. The covers were unrecognisable as the dirty, corroded lumps of aluminium that I'd left with him.

I took the covers up to Simon at "Bike-Aquablasting" yesterday and left them with him while I went for a pint of lunch and a sandwich at The George & Dragon in Stoke Golding. An hour and a half later Simon 'phoned to say that the job was a good 'un and I could collect them when I was ready. I have to say that the job was indeed a good 'un. The covers were unrecognisable as the dirty, corroded lumps of aluminium that I'd left with him.

Although the camshaft covers were unpainted when the bike left the factory, it was my intention to give them a coat of black engine paint before I refitted them. To that end, I'd bought a couple of aerosol spray cans of gloss black engine paint from Halfords. That turned out to be a complete disaster. The paint just did not want to coat the aluminium evenly. It just collected in globules on the surface. I thought that there must be some oil contamination on the surface so I cleaned off the paint and thoroughly cleaned the aluminium with acetone. That made no difference what-so-ever. The paint just did not seem compatible with aluminium, so the cover was cleaned again and I decided that they would go back on the bike unpainted. Honda knows best!!

The clutch cover, however, was a different matter. That had been painted black at the factory, and I wanted it black when it went back on. The engine is water cooled, of course, so the cases won't get as hot as they would on an air cooled engine. The engine paint I'd bought wasn't going to work if my experience with the camshaft cover was anything to go by, so I decided to take a chance and try the black Hammerite Smooth paint that I'd used on the fan shroud. I'm hoping that the cover won't get hot enough to cause a problem for the paint. I still didn't know if the paint would cover correctly but a light first coat confirmed that the paint did indeed cover evenly without the problem I had with the engine paint. I gave it two more coats and that will now be left over the Christmas holiday to cure completely before I put it back on the engine. When I removed the camshaft covers, the moulded rubber seals had hardened with age so I'd bought two new genuine Honda seals for the covers and eight new steel/rubber seals that fit under the bolt heads. As you would expect from Honda, when I offered the new seal up to the cover, it fitted perfectly but as the seal needs to be held in position whilst the camshaft cover is refitted, the Service Manual says to coat the groove in the camshaft cover with ThreeBond TB1521, "or something similar", before fitting the seal into the groove. That caused me a bit of a problem. An exhaustive on-line search only produced one supplier in the UK and they wanted £22 for a tube, plus another £12 for delivery. That seemed excessive, but it turns out that TB1521 is a chloroprene rubber adhesive of the contact variety, and on Royal Mail's prohibited list, so it has to delivered by a licensed courier... Bummer!!

As you would expect from Honda, when I offered the new seal up to the cover, it fitted perfectly but as the seal needs to be held in position whilst the camshaft cover is refitted, the Service Manual says to coat the groove in the camshaft cover with ThreeBond TB1521, "or something similar", before fitting the seal into the groove. That caused me a bit of a problem. An exhaustive on-line search only produced one supplier in the UK and they wanted £22 for a tube, plus another £12 for delivery. That seemed excessive, but it turns out that TB1521 is a chloroprene rubber adhesive of the contact variety, and on Royal Mail's prohibited list, so it has to delivered by a licensed courier... Bummer!!

Well... they did say "or something similar" so I started looking. Turns out that "Evostick" contact adhesive was as close as I was going to get. It proved to work very well indeed. I painted a very light coat into the groove in the cover with a small watercolour paintbrush. The new seal fitted into the groove precisely and stayed in place while I refitted the cover to the engine. The new steel/rubber seals were fitted to the bolts and they were tightened to the recommended 10Nm torque. That was job done... for the moment.

Sunday, 2nd January, 2022.

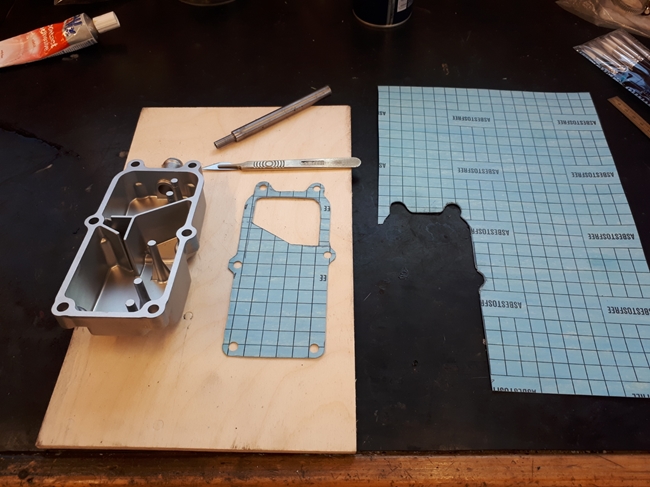

Christmas and New Year revelries successfully completed, it was time to start work again. It started well and then went seriously downhill. More about that later. First job was to make a new gasket for the breather box that sits on top of the rear camshaft cover as none were available from the usual suppliers. I'd bought a piece of 0.5mm thick gasket material and made a suitable hole punch for the bolts. Quite pleased with the result. That will do nicely. Before I fit that, however, I wanted to refit the rear camshaft cover. The rubber seal went back in a similar manner to the front one and the cover positioned on the rear cylinder head. This is where is started to go down hill. I fitted new rubber sealing washer to the bolts and set the torque wrench to 10Nm. That worked for three of the bolts... the forth promptly snapped off in the cylinder head... Bugger big time!! I'd forgotten that the Japanese make their bolts from something akin to "monkey metal". This bolt sheared at a lot less than the specified torque and I now had a bit of a problem, to say the least. The bolt had sheared well below the top surface of the cylinder head and there was nothing to get hold of. Than meant I had to use a drill, initially to attempt removal with a left hand extractor or failing that, to drill out the broken piece. Hopefully without damaging the thread but if all else failed, as a last resort to fit a Helicoil insert.

Christmas and New Year revelries successfully completed, it was time to start work again. It started well and then went seriously downhill. More about that later. First job was to make a new gasket for the breather box that sits on top of the rear camshaft cover as none were available from the usual suppliers. I'd bought a piece of 0.5mm thick gasket material and made a suitable hole punch for the bolts. Quite pleased with the result. That will do nicely. Before I fit that, however, I wanted to refit the rear camshaft cover. The rubber seal went back in a similar manner to the front one and the cover positioned on the rear cylinder head. This is where is started to go down hill. I fitted new rubber sealing washer to the bolts and set the torque wrench to 10Nm. That worked for three of the bolts... the forth promptly snapped off in the cylinder head... Bugger big time!! I'd forgotten that the Japanese make their bolts from something akin to "monkey metal". This bolt sheared at a lot less than the specified torque and I now had a bit of a problem, to say the least. The bolt had sheared well below the top surface of the cylinder head and there was nothing to get hold of. Than meant I had to use a drill, initially to attempt removal with a left hand extractor or failing that, to drill out the broken piece. Hopefully without damaging the thread but if all else failed, as a last resort to fit a Helicoil insert.

I have to admit, that the thought of attempting to drill a hole down the middle of a broken M6 bolt without it drifting off-centre and damaging the aluminium cylinder head, didn't fill me with joy. Time to put my engineering skill to work, I think. I had one thing going for me... The M6 thread in the cylinder head had been counter-bored and I could use that as a reference. It was 7mm diameter and about 1mm deep, so I turned up a steel bush that fitted into the counter-bore and acted as a guide for a 1/8" diameter centre drill. That worked a treat and I managed to dill into the centre of the broken bolt.

So far, so good... To be continued.

Next job... refit the clutch cover.  That went a lot better. The new gasket fitted perfectly and even appeared to have some sort of sealant applied to one side of the lower half. The paint on the cover had cured completely over the holiday and it looked a lot better than it did when I took it off. The original bolts were rusty so I replaced them with stainless flange screws. Not exactly original but they looked a lot better. The service manual said 12Nm but in light of what happened to the camshaft cover bolts, I was very careful when I tightened them up. 12Nm was nowhere near enough torque to shear a new stainless M6 screw, but I didn't want to strip the thread in the aluminium crankcase. I'd fitted new rubber seals to the internal damper plate and applied a dab of blue Loctite to the fixing screw. That coming loose could be unpleasant, bearing in mind all the ironmongery whirling around at a rate of knots in very close proximity! I put new "O" rings on the oil filler cap, dipstick and inspection cover just to complete the job properly.

That went a lot better. The new gasket fitted perfectly and even appeared to have some sort of sealant applied to one side of the lower half. The paint on the cover had cured completely over the holiday and it looked a lot better than it did when I took it off. The original bolts were rusty so I replaced them with stainless flange screws. Not exactly original but they looked a lot better. The service manual said 12Nm but in light of what happened to the camshaft cover bolts, I was very careful when I tightened them up. 12Nm was nowhere near enough torque to shear a new stainless M6 screw, but I didn't want to strip the thread in the aluminium crankcase. I'd fitted new rubber seals to the internal damper plate and applied a dab of blue Loctite to the fixing screw. That coming loose could be unpleasant, bearing in mind all the ironmongery whirling around at a rate of knots in very close proximity! I put new "O" rings on the oil filler cap, dipstick and inspection cover just to complete the job properly.

Monday, 3rd January, 2022.

I wanted to get the front end of the bike put back together, not least because I kept tripping over the front upper fairing where it sat on the workshop floor. There was, I found to my cost, that there was a very definite, and logical, order in putting things back together. I started with the radiator. The replacement that I bought from Germany had already been fitted with new mounting rubbers so the ones I'd bought were superfluous and would be added to my mounting stock of unused spare parts. Having fitted it to my satisfaction, I realised that there was no way that I could fit the spark plugs and plug caps to the front pair of cylinders. Bummer... it all had to come off again. I'd bought 4 new Honda spark plugs and two of them were checked for gap size (perfect, no adjustment necessary) and the threads given a little Copperslip grease. They were then fitted and tightened to 10Nm torque. The plug caps were pushed onto the plugs and the radiator re-installed. I fitted new stainless steel Jubilee clips to the radiator hoses and refilled the cooling system with new coolant specifically formulated for motorcycles. It took a little "squeezing of the hoses" to get the air out of the system. The header tank was filled to the "Upper" level with the same coolant. Any air remaining in the cooling system should be expelled through the header tank when the engine reaches working temperature.

Tuesday, 4rd January, 2022.

Fitting the top fairing and screen back on was not as straightforward as I expected it to be. None of the fixing holes seemed to line up and I had to "persuade" it back into position. It did eventually go back, only for me to realise that there was an electrical connector dangling where there shouldn't be one and I had to take the fairing back off to plug the connector into it's mating half in the wiring harness. I never had any of this trouble with my old British bikes!! Fortunately, the front and lower fairing panels went back without any drama. Six of the fixings were plastic trim buttons and new ones were used as a matter of course. I'm leaving the two side panels off for the moment. The right hand side panel has a couple of small cracks in that need to be addressed before they get any worse. I'll run the engine to circulate the coolant and oil, also to make sure the fan switches on when the coolant is up to temperature. I'll check for any leaks and I may need to top up the coolant and oil before I put the side panels back on.

Fitting the top fairing and screen back on was not as straightforward as I expected it to be. None of the fixing holes seemed to line up and I had to "persuade" it back into position. It did eventually go back, only for me to realise that there was an electrical connector dangling where there shouldn't be one and I had to take the fairing back off to plug the connector into it's mating half in the wiring harness. I never had any of this trouble with my old British bikes!! Fortunately, the front and lower fairing panels went back without any drama. Six of the fixings were plastic trim buttons and new ones were used as a matter of course. I'm leaving the two side panels off for the moment. The right hand side panel has a couple of small cracks in that need to be addressed before they get any worse. I'll run the engine to circulate the coolant and oil, also to make sure the fan switches on when the coolant is up to temperature. I'll check for any leaks and I may need to top up the coolant and oil before I put the side panels back on.

Thursday, 6th January, 2022.

Broken camshaft cover bolt... Continued. I had three plans of operation to remove the broken camshaft cover bolt from the rear cylinder head. Having already drilled a centre hole in the broken piece, "Plan A" was to use a 3.2mm left hand drill with the guide bush I'd made. Sometimes, if the broken bolt isn't tight, a left hand drill will actually unscrew the broken piece. If that didn't work, then "Plan B" was to use a 4.8mm L/H drill and if necessary, a left hand spiral extractor. Failing that, "Plan C" was to drill the whole lot out and fit an M6 Helicoil thread repair insert.

Having now got all the necessary tools in place, I put "Plan A" into operation... Happy days... The broken section of bolt unscrewed immediately. That was very definitely a RESULT!! I'm still waiting for the new bolts that I'd ordered to be delivered. Hopefully, they'll arrive in today's post, and I can finish putting the rear camshaft cover back on.

Having now got all the necessary tools in place, I put "Plan A" into operation... Happy days... The broken section of bolt unscrewed immediately. That was very definitely a RESULT!! I'm still waiting for the new bolts that I'd ordered to be delivered. Hopefully, they'll arrive in today's post, and I can finish putting the rear camshaft cover back on.

In the meantime, I thought I'd put the left hand side panel back on. There's nothing behind it that I will need to get to. If you've been paying attention, dear reader, you'll no doubt remember that I sourced a set of ten new DZUS fittings to replace the very rusty items that currently secure the side panels. You'll probably be amused to know that from a choice of two sizes, I bought the wrong ones. Bummer. Ok... I've now ordered the correct ones and will refit the side panel when they arrive in a day or three. Even so, they've cost me a lot less that the £120+ that Mr Silver wanted for a set of ten identical fittings dressed up in Honda packaging.

A little later in the day... As I'd hoped, the new camshaft cover bolts turned up in the post so it was back down the workshop for me. This time, the cover went back onto the cylinder head without any drama. Hooray!! Just one more little task this afternoon and that was to reinstate the air box, complete with a new filter. With the exception of refilling the engine with oil, that's the service completed. Oil, air and fuel filters have been replaced. Coolant changed. Valves checked. New spark plugs installed... All done.

Saturday, 8th January, 2022.

Just tidying up a few loose ends today. The replacement petrol tank has been compounded and polished to remove the minor surface blemishes. Dent free, it's in much better nick that the one that was on the bike when I bought it. I've refitted the fuel tap and fuel gauge sender unit with new "O" ring seals. I gave them a light smear of "Molycote" silicone grease before assembly. I've fitted new rubbers to the front mounting, the sides where it sits on the frame rails, and the rear bolt. All were give the "Molycote" treatment. Apart from wriggling the sender unit into the tank, which was a bit fiddly, it all went remarkably smoothly. I've ordered a new, self adhesive, protector for the rear, and will fit that when it arrives.

Just tidying up a few loose ends today. The replacement petrol tank has been compounded and polished to remove the minor surface blemishes. Dent free, it's in much better nick that the one that was on the bike when I bought it. I've refitted the fuel tap and fuel gauge sender unit with new "O" ring seals. I gave them a light smear of "Molycote" silicone grease before assembly. I've fitted new rubbers to the front mounting, the sides where it sits on the frame rails, and the rear bolt. All were give the "Molycote" treatment. Apart from wriggling the sender unit into the tank, which was a bit fiddly, it all went remarkably smoothly. I've ordered a new, self adhesive, protector for the rear, and will fit that when it arrives.

With the tank in position, the petrol pipes were connected and the sender unit plugged into the wiring harness. The only other thing I did today was to replace the six DZUS clips on the belly pan moulding. The old ones were very rusty and a couple of them had broken. Another broke as I removed it, so they were well past their "best before" date and needed replacing. The four clips on the side panels will also be replaced in due course. Oh yes... I've poured 3 litres of the very best, fully synthetic, oil into the engine. It's showing a little above the full mark on the dip-stick at the moment, but will drop back once the new oil filter can has been filled.

Sunday, 9th January, 2022.

Well, I didn't see that coming. Having refitted the petrol tank yesterday, this morning I thought I would put some petrol in and see if the engine will start. I was going to empty a full 10 litre petrol storage can into the tank but after pouring in a couple of pints, I thought I'd better just check that all was well under the tank. It wasn't. There was a steady drip from the fuel tap...  Buggeration!! I hastily took the tank off again and put it on the bench. It was difficult to see exactly where the leak was but it appeared to be from between the alloy body casting and the steel tap spindle retaining plate. That's a riveted assembly and not user serviceable. Ho hum... I emptied the tank and took the tap off. I had used a new "O" ring seal and cleaned the joint faces so I'm reasonably sure it's not leaking from there. It could be that during the couple of months that the tap has been off, the internal seal(s) may have dried out and shrunk a little. I'll submerge the tap in petrol for a couple of days and see if it makes any difference. That's something we had to do with old British bikes. I expected better from Honda! There is a second hand tap on eBay that I may look at or a Japanese website is apparently selling new OEM items for around 75USD. Time will tell which way I decide to go.

Buggeration!! I hastily took the tank off again and put it on the bench. It was difficult to see exactly where the leak was but it appeared to be from between the alloy body casting and the steel tap spindle retaining plate. That's a riveted assembly and not user serviceable. Ho hum... I emptied the tank and took the tap off. I had used a new "O" ring seal and cleaned the joint faces so I'm reasonably sure it's not leaking from there. It could be that during the couple of months that the tap has been off, the internal seal(s) may have dried out and shrunk a little. I'll submerge the tap in petrol for a couple of days and see if it makes any difference. That's something we had to do with old British bikes. I expected better from Honda! There is a second hand tap on eBay that I may look at or a Japanese website is apparently selling new OEM items for around 75USD. Time will tell which way I decide to go.

Monday, 10th January, 2022.

The fuel tap has been left submerged overnight in a jar of petrol. This morning I took it out and dried it off. It looked exactly the same, of course. I took extra care ensuring the O-ring mating surfaces on the tank and tap were clean, then assembled the tap back into the tank. So... has it made any difference? I'm happy to say that it looks like it has. I poured in a few pints of petrol and the tap has so far been drip free. I'll leave it for an hour or so before I put the tank back on the bike, just to be sure.

A little later... I left the tank for a couple of hours and was happy to see that the tap was still drip free. Hooray!! The tank has been re-installed on the bike, connected up and 10 litres of petrol poured in. Happily, it was still leak free. As you would expect, with a dry tank, the "Fuel Low" warning light was on and the fuel gauge was showing empty. According to the specification in the Service Manual, the tank holds 21 litres. The fuel gauge sender unit in the old tank was wildly inaccurate, the gauge showing full with around 7 litres in the tank. This one was much better. With 10 litres in,  the warning light was out and the gauge was showing just under 3/4 full. Still a bit optimistic but at least I know where it is.

the warning light was out and the gauge was showing just under 3/4 full. Still a bit optimistic but at least I know where it is.

With everything connected and the tail fairing back in place, it was time to see if she will still run. It took a few seconds of cranking over before she fired and ran but run she did. I set it to a fast tick-over and left it running. I wanted to get it hot enough to turn the cooling fan on. I know the switch worked when immersed in boiling water but I needed to know that it would work on the bike. It took 15 or 20 minutes before the cooling fan did, indeed, switch on. Great. I set the tick-over back to around 1100 r.p.m. then switched off.

I checked that all the electrics worked and was somewhat miffed to discover that the right hand rear indicator wasn't working. Peering under the rear cowl with the aid of a torch, I could see that the earth wire to the bulb holder was not connected. At first I thought that the blade on the bulb holder was broken but once I'd got the rear fairing off and back on the bench, I could see that it wasn't broken, the push-on receptacle had just fallen off. That was the result of a "bodge" by a previous owner, who had twist joined a short length of wire onto the harness wire and used the wrong size receptacle. That has all now been repaired to my satisfaction and the indicator light is working again.

The last thing I did today was add a little "bling" to the rear wheel. It's a cover over the wheel nuts that looks a bit like the single nut rear wheel mounting that Ducati use. Whatever... I think it looks ok so it will stay. [Actually, it didn't... stay, that is. It's lying somewhere at the side of the A1(M) in Cambridgeshire!!] Well that's it, for the moment. The only thing outstanding is to put the side panels back on but I can't do that until the longer DZUS screws arrive in the post.

Tuesday, 11th January, 2022.