Monday, 9th December, 2019

Well, I have to say that this was a little unexpected. I'd seen that this bike was up for auction on eBay about a week ago and thought it looked very nice indeed. I'd been looking, half heartedly, for an affordable CS competition model ever since I'd missed one at a Cheffin's auction a few years ago. Unfortunately, those that I'd seen for sale were always out of my price range. Anyway... I was watching the final few minutes of the auction for this bike with Christine and Dave "The Hat" looking over my shoulder. The current bid was £5,400 but I'd not seen one for sale at less than £8000 so I was confident that as usual on eBay, there would be a flurry of bids in the last few seconds. To demonstrate this to Christine and Dave, I put in a bid of £6000 with a minute to go. I was the high bidder at £5,900. Very much to my astonishment, it remained that way until the end of the auction. There were no other bids... I'd actually won it!! It's a good job I had the money to pay for it!!

Friday, 13th December, 2019.

As requested on the auction web page, I'd paid a £250 deposit via eBay immediately after the auction so today I drove over to Huggy's Speedshop in Atherstone, to have a look at the bike and pay off the balance. On the face of it, it looks ok. It had been imported from the west coast of America where it had been since 1956. It had apparently been in a private collection for many years and not used. It will need some work. The engine runs ok so the Lucas racing magneto is working but all the other electrics are dead. The battery looks like one of the original 'black box' Lucas jobs which haven't been made for decades so it could be just a simple case of a dead battery. At worst, it may mean a rebuild to the dynamo. I won't know until I get it home. The seat has a few little tears in the cover, possibly due to the vinyl hardening in the California sun! That may be a job for J.K. Leighton to sort out. I've arranged for the bike to be delivered and I'm waiting for the courier to contact me with the dates etc.

Monday, 13th January, 2020.

Why does it take so long for 500cc AMC machines to be delivered? When I bought "Bess", it was 5 weeks from the time I paid before I clapped eyes on her. It seems the same will be said for this new machine. OK... I know Christmas and the New Year celebrations have got in the way but it still seem a long time. Finally, after a number of 'phone calls, things are moving. I spoke to the guy at Huggy's this morning and he informed me that the bike was actually collected last Friday and should be with me this week. I asked for, and got, the contact number and name of the courier so I gave him a call as well. He confirmed that he has the bike and is hoping to deliver it tomorrow (Tuesday) but will 'phone me later today to confirm the arrangement. Hooray!!

Tuesday, 14th January, 2020.

True to his word, the courier phoned back later yesterday and confirmed delivery for today. He arrived around 10:30 this morning and off-loaded the bike. A quick inspection showed no damage had been caused in transit. That was good news. The bike was wheeled into the garage and made secure. As Bess is still in the workshop, I can't start on this one yet but hopefully, I'll get her in there soon for a good check over. Then I can formulate a 'Plan of Action'.

True to his word, the courier phoned back later yesterday and confirmed delivery for today. He arrived around 10:30 this morning and off-loaded the bike. A quick inspection showed no damage had been caused in transit. That was good news. The bike was wheeled into the garage and made secure. As Bess is still in the workshop, I can't start on this one yet but hopefully, I'll get her in there soon for a good check over. Then I can formulate a 'Plan of Action'.

Thursday, 16th January, 2020.

A bit of bike 'shuffling' today. The rear wheel I borrowed from Steve in Boston was fitted into Bess and she was wheeled out of the workshop and into the garage. That left the workbench clear for the G80CS. A little awkward to manage single handedly but she's on and secured. Only had a cursory look around but a couple of thing stuck out. First, the tyres will need replacing before it's ridden. The front tyre is cracked around the sidewall and between the treads. The rear tyre is a little better but the date stamp shows it was made 17 years ago so that is well past it's use-by date. The "battery" is a replica Lucas 'black box' containing a tiny sealed 6v battery.  It was flat so I've put it on charge to see if it can be recovered but I'll source a new, larger battery in due course. There is a fuse holder in the main battery lead but no fuse fitted. That may, or may not, be indicative of a wiring problem. Time will tell.

It was flat so I've put it on charge to see if it can be recovered but I'll source a new, larger battery in due course. There is a fuse holder in the main battery lead but no fuse fitted. That may, or may not, be indicative of a wiring problem. Time will tell.

I've taken photographs of the numbers on the frame, engine and gearbox. These have been sent off to Roy Bellett, the club Dating Officer, along with a cheque for £10. Hopefully he will be able to supply the documents I'll need to obtain an age related registration.

The battery has been on charge for 6 hours and it's still flat so I'm pretty sure that it's u/s. A new battery, the same as the ones fitted to Alice and Bess, will be required in due course.

Tuesday, 21st January, 2020.

I've had a chance to have a better look around the G80 this week and come up with a provisional "To Do" list. New tyres and a replacement battery are already on the list. The first thing I looked at was the speedometer. It only has 3 miles on the odometer so may or may not be working. I disconnected the drive cable at the rear wheel and at the speedometer. Giving it a twist at one end and watching the other confirms that the cable is not broken and it moves smoothly.  That's a good sign. With the speedo reconnected and the cordless drill running in reverse at the wheel end, the speedo needle moved round the dial as it should. That's a better sign. The trip odometer reset knob has been broken off so it's going up to Russell at Chronometric Instrument Services for an overhaul. The legend on the dial... "S 491/3/L"... indicates that it is the correct speedometer for the bike.

That's a good sign. With the speedo reconnected and the cordless drill running in reverse at the wheel end, the speedo needle moved round the dial as it should. That's a better sign. The trip odometer reset knob has been broken off so it's going up to Russell at Chronometric Instrument Services for an overhaul. The legend on the dial... "S 491/3/L"... indicates that it is the correct speedometer for the bike.

Next job was to check out the electrics. A previous owner had fitted a blade fuse holder but there was no fuse fitted. I replaced a fuse and checked the circuit with a multi-meter. With the everything switched off, the meter showed "open circuit" so I was happy to connect up the battery that I'd borrowed from Alice. Surprise, surprise... The headlight, tail light and stop light all work pretty much as they should... as do the horn and speedometer light. The ammeter also shows a discharge with the lights on. That is very good news. The only problem is that the pilot light in the headlamp is missing. For some reason, the hole in the reflector has been enlarged so that a normal pilot light holder will no longer fit. That will have to be sorted either by finding another 'original' reflector or sourcing a modern replacement. Not sure which way to go at the moment. The headlamp bulb is of a sort that I've not seen before. You have to take the reflector out of the rim to change it. That may well influence my choice of replacement. I don't know if the dynamo and regulator are working. I loosened the cover on the end of the dynamo and as far as I can tell, the dynamo is mechanically ok. The brushes look well worn and the 4BA thread for the cable securing screw in the plastic end cap is stripped so it's not totally without it's problems. I may well remove it and send it up to Paul Dunn for a check-up and possible rebuild. I won't be able to check the regulator until the dynamo is sorted and the engine running.

Wednesday, 29th January, 2020.

I've finally got all the documentation ready to apply for a registration number and that was all sent off to the DVLA today. Hopefully, there won't be any problems but I'll just have to wait and see. I've also spent a modest amount of hard earned cash on a new headlight lens/reflector unit, a new rear light and a piece of aluminium plate that will be used to fabricate a new rear number plate. The headlamp unit is a 6.1/2" Miller item similar to the ones fitted to the AMC lightweight bikes. It takes the normal British Pre-Focus (BPF) bulb and has the aperture for the 'plug-in' pilot light. I may well use a modern LED headlamp 'bulb' in place of the older tungsten lamp.

to the ones fitted to the AMC lightweight bikes. It takes the normal British Pre-Focus (BPF) bulb and has the aperture for the 'plug-in' pilot light. I may well use a modern LED headlamp 'bulb' in place of the older tungsten lamp.

The old rear light assembly was past it's sell-by date and not fit for purpose but the original red lens with 'LUCAS' moulded into it was unbroken and will hopefully be used with the new bulb holder part to maintain some semblance of originality. That will be attached to the top of the new number plate and will hopefully be as close to the original as makes no difference.

Saturday, 8th February, 2020.

Some good news and some not so good. First off, I've heard back from the DVLA and they wanted another document... an original registration certificate from the country of origin, namely the US of A, or a letter of explanation as to why I don't have one. I've supplied the latter and hope it will satisfy them. That was sent off a week ago and I've not heard back from them... which may or may not be a good sign.

The new number plate is finished and fitted. I've used a new rear light back plate and bulb assembly but I've fitted the original red lens that has "LUCAS" moulded into it rather than the reproduction one that doesn't. That will maintain some semblance of originality. The speedometer that I sent off to Chronometric Instrument Services came back this morning and looks good. That has been fitted back above the headlight. I've also taken off the old handlebars, control levers and removed all the control cables. A new set of handlebars have been ordered and hopefully, will be here by the middle of next week. The valve lifter cable and the magneto advance cable look in good condition so I'm hopefully going to be able to keep those and re-use them. I have a new clutch and front brake cable that I bought for the M18S but didn't use so I hoping they will be ok for this bike. All the others I will replace with new ones. The control levers I'll polish up and put back onto the new handlebars.

Tuesday, 11th February, 2020.

Yesterday was a mixed day... I was on the road at 06:30am, driving down to Luton to attend the funeral of my friend, Malachy. I'd known him ever since I was playing in an Irish music group in the mid 1970s. He used to jam with us in the Moulder's Arms and played a mean accordion. At 57, he died far too young. Anyway.... When I got back home, there was an envelope from the DVLA waiting for me. Yippee... it was a new V5C registration document. The bike now has an age related, non-transferable number... "741 XVJ".

That wasn't the only thing waiting for me... The new handlebars had also arrived. They are the same, "US export" style as the originals which have a higher rise than the UK touring bars and will look better than the old ones.

Thursday, 13th February, 2020.

The new clutch cable that I bought from AMC Classic Spares for the AJS M18S was unsuitable for this bike too and for the same reason. The inner bowden cable was too long and the adjuster was only engaged by about two threads. I've ordered a clutch cable kit from Venhill, as I did for the AJS, and will make up a cable specifically for this machine.

I've stripped off the old wiring and started to rewire the bike. This one has a 5 pin plug and socket in the underside of the headlamp shell to facilitate the removal of the headlamp for competition use. I've un-soldered this from the old harness and rewired it with new, thin wall cables. The front half of the harness is now complete and tested. The headlight and handlebar switch gear all work correctly. A new battery has been ordered, as has a new solid state dynamo regulator. When they arrive, I'll complete the wiring.

Saturday, 15th February, 2020.

I've completed a few more tasks but nothing really worthy of a picture or two. First off, I've had the front wheel out. When I pushed the bike round to the workshop a few weeks ago, I noticed that something was rubbing in the front hub. Well, I've found out what it was. The brake plate retaining nut was very loose and the brake plate was wobbling about all over the place. The lining are in very good condition and won't need replacing at the moment. I cleaned all the components and reassembled everything, making sure the retaining nut was tightened securely. That done, a new front brake cable was fitted and adjusted.

The new AGM battery arrived yesterday and that has been installed, with a 15A fuse in the +ve, ground lead. Now I needed to know if the dynamo was fully functional. To test it, I needed to remove the primary drive, or at least, part of it. The chain case out cover came off easily enough and I was surprised and pleased to find that both the inner and outer covers are in exceptionally good condition. There was no distortion or bending and no evidence that either the primary drive chain or the dynamo drive chain had ever come into contact with the any of the tinware. I stripped out the clutch and that also is in great condition, with the exception of the clutch pushrod. Strangely enough, that had to be pulled out with a pair of pliers and proved to be bent. How you manage to bend a 5/16" diameter steel pushrod, I just don't know. Fortunately, I have a spare one so it's no real problem. That just left the crankshaft nut which was removed with the aid of my air impact wrench. I slid the shock absorber spring and cam off the mainshaft. Now I could test the dynamo. I had no idea how long the bike had been standing so to make sure the field coil pole piece was magnetised and correctly polarized, I 'flashed' the field coil with a 12v battery. Having done that, I connected the "D" & "F" terminals on the dynamo together and connected them to the negative (-VE) battery terminal. Now if I connect the positive (+VE) battery terminal to the dynamo body, it should run as a motor, in the direction that it would normally been driven by the engine. Did it? Oh yes!! That is very good news as it's an indication that the dynamo is in serviceable condition and hopefully will work as it should with the motor running.

Monday, 17th February, 2020.

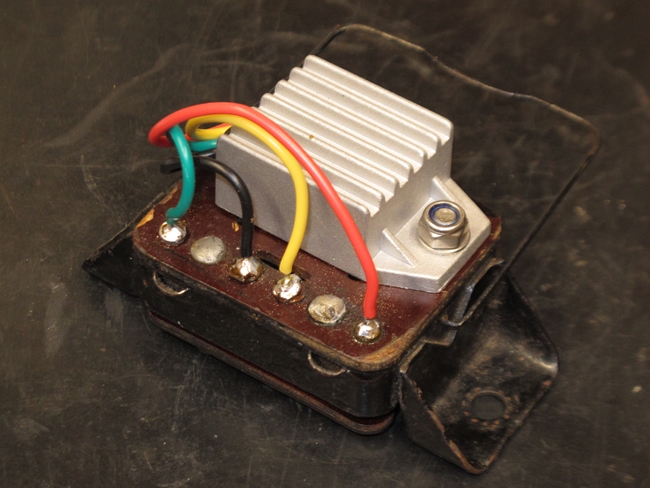

The wiring is just about complete and tested. All works as it should. All I have left to do is bolt the voltage regulator back into position and plug in the four connectors. While I'm on the subject of regulators, the original MCR2 unit looked to be in good nick but it's 60 odd years old and a potential source of problems. On both the G3/LS and the M18S, I've replaced the old mechanical regulator with a more reliable modern solid state regulator and they have proved to be trouble free... so far! With that in mind, and wanting to maintain at least a modicum of originality, I've stripped the coils and contacts out of a scrap MCR2 and mounted a solid state regulator inside. That will maintain the original look of the bike but hopefully give me reliability. I'll keep the original unit intact and should I, or a subsequent owner, want to return to the original specification, then it will just be a case of swapping out the modified box and putting the original box back in.

The wiring is just about complete and tested. All works as it should. All I have left to do is bolt the voltage regulator back into position and plug in the four connectors. While I'm on the subject of regulators, the original MCR2 unit looked to be in good nick but it's 60 odd years old and a potential source of problems. On both the G3/LS and the M18S, I've replaced the old mechanical regulator with a more reliable modern solid state regulator and they have proved to be trouble free... so far! With that in mind, and wanting to maintain at least a modicum of originality, I've stripped the coils and contacts out of a scrap MCR2 and mounted a solid state regulator inside. That will maintain the original look of the bike but hopefully give me reliability. I'll keep the original unit intact and should I, or a subsequent owner, want to return to the original specification, then it will just be a case of swapping out the modified box and putting the original box back in.

Saturday, 22nd February, 2020.

Most of the work I'd intended to do on this bike has now been done. The wiring is finished, tested and working. The control cables have all been replaced... Why is it that cables that are supposed to be correct for the bike seldom are? The front brake and clutch cables I've made up from scratch using heavy duty components from Venhill because the ready made ones I bought didn't fit ... by a long way. The exhaust valve lifter and magneto advance cables were in very good condition and have been reused. The throttle and air slide cable I bought ready made from AMOC Spares. The throttle cable just about fitted but I had to shorten the outer conduit on the air slide cable by about 3/4" before I was happy with it.

The magneto points have been cleaned and gapped. The timing has been checked and is close enough to being correct. If anything, it's slightly advanced but I can back it off manually with the lever on the handlebars if necessary. I was a bit concerned when I couldn't get a spark but that turned out to be a duff spark plug. A new Champion N4C gave a good fat spark. The fuel tank has been bolted back on with new rubber mounts at the rear. The carburettor jets have been cleaned and checked. They are all correct but I may have to increase the main jet by a couple of sizes to compensate for the ethanol in the fuel we're served these days. So... what's left to do? The tyres need to be replaced, the seat need to be recovered and the primary chain case outer cover needs to be put back on. I need a new rubber seal for that. I should have ordered one when I bought the cables from AMOC Spares but it slipped my mind. Now I'll have to pay another lot of postage just to get the rubber seal. Ho hum.

Monday, 24th February, 2020.

Only spent an hour or so in the workshop today. I wanted to check on the vital fluids. First it was the gearbox. I dropped out the drain plug and was rewarded with... nothing. The gearbox was empty; just a drop or two of oil came out into the drain tray. At least is was clean oil! I'm hoping that the gearbox had been emptied, prior to the bike being shipped over from the States. Huggies had run the bike but I'm hoping that they didn't run it for too long. I replaced the drain plug and refilled the gearbox with fresh SAE50 straight mineral oil. Next it was the swinging arm reservoir. There wasn't a drain plug for that... The oil leaks out naturally through the bushes!! I topped that up with fresh Castrol "D", a straight SAE140 as per the manual. That just left the engine oil tank. It was barely half full, only a couple of pints of oil in there but again, it was fresh clean oil... It looked like a 20W50 and I suspect that Huggies had just put enough into the empty tank to check that the engine ran ok. It was the wrong grade and not suitable so that was emptied out and the tank refilled with fresh SAE50 mono-grade oil, the same as the gearbox. That just leaves the primary chaincase to add oil to once I've got the outer cover back on.

Tuesday, 25th February, 2020.

The best laid plans of mice, etc. The new primary chaincase sealing rubber arrived this morning so I thought I'd just pop out to the workshop and put the chaincase back together. Somewhere along the line, I must have offended the "Small God of Gearbox Oil Leaks" (with apologies the Terry Pratchett) as there was a significant pool of fresh oil under the bike. It was obvious that the oil was leaking from the gearbox but the exhaust pipe was in the way and I couldn't see exactly where the oil was coming from. There was too much oil to ignore so I had to delve a bit deeper. The exhaust pipe and silencer came off more easily than I expected, giving me access to clean off all the leaked oil with brake cleaner and paper towels. There was no obvious holes or cracks in the casings so I left it while I had a pint of lunch. I returned an hour or so later to discover that the oil was leaking from the joint between the main gearbox case and the inner cover. Bummer... Fortunately, the Burman GB52 gearbox is very easy to work on and can be stripped in situ without removing it from the frame. The 5 screws holding the outer cover showed no signs of abuse but I had to use the impact driver to loosen them. The outer cover can be removed without having to take the kickstart lever or gear change lever off. It was a bit mucky inside with a fair amount of black sludge but it wiped away easily. In contrast to the outer cover screws, the three remaining inner cover screws were loose... very loose by at least one complete turn. That was almost certainly the reason for the leak. The gaskets were broken and not doing anything to stop oil leaking.

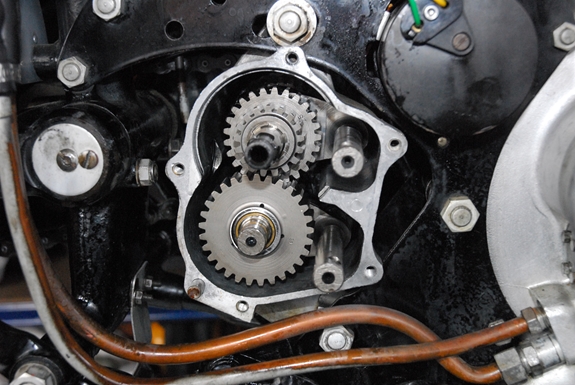

While I'd got the covers off, it made sense to check the internals for wear. The major components are all in excellent condition. There is no pitting on the gear teeth and nothing broken. There are however, a few of the small components that I will replace, either because of wear or just because it makes sense to replace them. The two dowels that locate the selector rods into the selector cam show significant wear and will be replaced as will the selector cam detent plunger as that is also worn. Best to replace them now and not wait for them to cause a problem later. The mainshaft nut locking washer will be replaced as a matter of course, as will the three oil seals in the outer cover. I've also decided to change the ball race that supports the kickstart end of the mainshaft. It doesn't feel particularly worn but for the sake of a couple of quid, I'll change it.

While I'd got the covers off, it made sense to check the internals for wear. The major components are all in excellent condition. There is no pitting on the gear teeth and nothing broken. There are however, a few of the small components that I will replace, either because of wear or just because it makes sense to replace them. The two dowels that locate the selector rods into the selector cam show significant wear and will be replaced as will the selector cam detent plunger as that is also worn. Best to replace them now and not wait for them to cause a problem later. The mainshaft nut locking washer will be replaced as a matter of course, as will the three oil seals in the outer cover. I've also decided to change the ball race that supports the kickstart end of the mainshaft. It doesn't feel particularly worn but for the sake of a couple of quid, I'll change it.

I washed the internals in white spirit and rebuild the box. I can't put the rest back together until the replacement parts and new gaskets arrive. There are two suppliers that I use for Burman parts... Draganfly Motorcycles and the AMOC Spares Dept. Unfortunately, neither of them had ALL the parts I needed but between them, I can get everything I want; it just means two lots of postage charges, unfortunately.

Friday, 28th February, 2020.

On the face of it, you'd have thought that what was a simple oil leak would be a simple job to fix... right? Wrong... The gearbox was stamped "GB27 K 55" on the edge of the inner cover, which indicates that the gearbox was actually made in 1955 so I looked in the '55 parts list for the part numbers of the items I wanted to replace. The selector cam detent plunger was listed as part no. G-42-3, so that was the part I ordered from AMOC Spares. When it arrived, I was a little perplexed to find that it wouldn't fit into the gearbox inner cover. I checked the outside diameter with a micrometer. The original plunger measured 0.499", the replacement measured 0.511". My first thought was that the part had been made incorrectly but checking on the AMOC Spares web site, they listed two plungers... G-42-3 (which they state replaces the earlier part G-42-1) and an "oversize" plunger G-42-3/13 which was made with the outside diameter at 13mm (0.511"). I suspected that they'd sent me the oversize plunger by mistake so I gave them a call. The gentleman I spoke to (Andrew) told me that they didn't have any oversize plungers. The few plungers that they had left in stock were all in the G-42-3 box. After a little persuasion, I got him to go and measure those that they had left. They were all 13mm diameter. I guessed (incorrectly, as it will turn out) that they'd just got stored in the wrong box. I arranged to return the oversize plunger for a refund.

When it arrived, I was a little perplexed to find that it wouldn't fit into the gearbox inner cover. I checked the outside diameter with a micrometer. The original plunger measured 0.499", the replacement measured 0.511". My first thought was that the part had been made incorrectly but checking on the AMOC Spares web site, they listed two plungers... G-42-3 (which they state replaces the earlier part G-42-1) and an "oversize" plunger G-42-3/13 which was made with the outside diameter at 13mm (0.511"). I suspected that they'd sent me the oversize plunger by mistake so I gave them a call. The gentleman I spoke to (Andrew) told me that they didn't have any oversize plungers. The few plungers that they had left in stock were all in the G-42-3 box. After a little persuasion, I got him to go and measure those that they had left. They were all 13mm diameter. I guessed (incorrectly, as it will turn out) that they'd just got stored in the wrong box. I arranged to return the oversize plunger for a refund.

I gave AMC Classic Spares a call and they had G-42-3 plungers in stock so I ordered one. An hour or so later I had an email from Steven at AMC Classic spares as he'd seen a mention of the problem in a post I made to the AMOC Forum. He told me that the plunger changed part numbers from G-42-1 to G-42-3 at the end of 1953 when the diameter was increased from 1/2" to 13mm. As my gearbox was from 1955, I'd ordered the correct part. The replacement G-42-3 plunger from AMC arrived today and of course, it was the larger 13mm diameter. I'd already replied to Steven's email and told him that it was definitely the smaller 1/2" diameter plunger that I needed, despite my gearbox dating from 1955 and should have had the the larger one. So that went back to AMC Classic spares today. Fortunately, they also have the earlier G-42-1 plunger so I've asked them to send one of those. Why my gearbox has the earlier plunger, despite dating from '55, I don't know. Hopefully, it will all get put back together when the smaller diameter plunger finally arrives.

Thursday, 5th March, 2020.

On Monday, I drove into Birmingham city centre. I took the dual seat the R.K. Leighton to be re-covered. I could have entrusted it to Parcel Force or some other courier but I had time on my hands and I was curious to see what sort of set-up they had. They operate from a small industrial unit, off a one-way street. There were parking bays along the street but they were all occupied so it was fortunate that there a couple of spaces available in the industrial park. I rang the bell and was duly greeted by Andrew, who was expecting me as I'd let them know that I was coming. He took the seat and remarked that it was extremely rare to find one with a seat-pan in such good condition. Mostly they are rusted out and need a considerable amount of welding to restore them. Fortunately, mine would need none of that. It will be around three weeks before I get it back.

Today, the new, smaller diameter detent plunger arrived from AMC Classic Spares. That meant I could complete the gearbox rebuild which I did this afternoon. Having got the outer cover back on and screwed up tightly, I was just a bit perturbed to find that I couldn't select first gear... or any gear, come to that. I mentally ran through how I'd assembled it and couldn't think of anything I'd done, or not done, that would stop the gear selector mechanism from working. I suspected that is was just the new detent plunger engaging fully into the selector drum that was the problem. I gave the gear change lever a good hard upward yank and first gear was engaged. In fact, once I'd filled the box with oil, I found that I could engage all four gears with a firm movement of the lever.  Good..... I'm happy again. No oil had dripped out after a couple of hours so I'm optimistic that I've cured the leakage problem.

Good..... I'm happy again. No oil had dripped out after a couple of hours so I'm optimistic that I've cured the leakage problem.

Monday, 16th March, 2020.

I've had a short break away from bikes and spent a week fishing for pike (with moderate success) on the River Bure with my buddy, Les. Now it was back to the reality of the G80CS. I'm happy to say the the gearbox now appears to be 100% oil tight. During the break, I ordered a pair of Mitas E-05 Enduro tyres and a pair of Michelin heavy duty inner tubes. The tubes arrived today but I'm not expecting the tyres until later in the week as they are coming from Germany. So... today I removed both wheels and after an epic battle with a very old and very hard pair of tyres, they eventually lost and I now have to find somewhere to dispose of them, responsibly. Nipping out after dark and chucking them in a local drain, as the locals have suggested, is not an option. The two security bolts in the rear wheel have seen better days so I will replace them all, including the one in the front wheel.

The rim tapes will also be replaced. I was a little surprised to see that the ends of the spokes that protrude through the nipples had not been ground off. Some of them stuck through by nearly 3mm. They hadn’t punctured the inner tube but the potential was there for them to do so, so I spent an hour or so with the Dremel smoothing them all off... all 80 of them!

I was very pleased to find that the rear brake drum and brake shoes have been replaced at some point. Difficult to say how long ago, but they certainly don't have many miles on them.

Wednesday, 18th March, 2020.

Just a brief update...

Just a brief update...

I had a phone call from Andrew at R.K. Leighton this morning. The work on the seat has been completed and it will be posted back to me on Friday, so I should get that sometime next week.

One of my new tyres arrived yesterday... the rear 4.00-19" Mitas E-05 and it's a beast of a tyre. It's suitable for both road and trail riding so if I fancy taking the CS into its natural environment and up a few green lanes I know the tyres will handle it. The front tyre has been delayed slightly but I have the tracking information and it's currently en-route from Poland!! It should arrive in a couple of days or so. I telephoned "Gildos Motorcycle Centre" in Wisbech and they are quite happy to fit the new tyres to the wheels for a modest payment. That's good, 'cos there's no way I'm going to get that rear tyre on without a tyre fitting machine. Oh, yes... Today is my birthday. "Happy Birthday, John".

Friday, 20th March, 2020.

Good news... I have both tyres, now, and they've been fitted to the wheels. Thank you Adam at Gildos... who just happens to be the son-in-law of my next door neighbour, Tug. Right... Having done the waffle bit, the wheels are back on the bike. The only thing left to do now is put the seat back on when it arrives sometime next week. I don't need the bike on the workbench to do that, so tomorrow, the G80CS will go into the garage and Bess will come back into the workshop to enable me to sort out the oil leak.

Saturday, 21st March, 2020.

The G80CS (which still doesn't have a girls name as do all my other bikes) was wheeled out of the workshop this morning. It still needs a seat but that can be fitted when it arrives. I'd only ever seen the bike running in a video so now was the time to see if it started and ran. I poured half a gallon of premium unleaded, that had been dosed with Castrol Valvemaster, into the 2 gallon tank. After a few tentative prods (I wasn't sure yet where the advance/retard lever needed to be set) I gave it a heft kick and she fired up. Yippee... Oh... hang on... The ammeter isn't showing a charge. With the lights switched on, there was a very definite discharge which revving the engine did nothing to alleviate. Bummer!!

The G80CS (which still doesn't have a girls name as do all my other bikes) was wheeled out of the workshop this morning. It still needs a seat but that can be fitted when it arrives. I'd only ever seen the bike running in a video so now was the time to see if it started and ran. I poured half a gallon of premium unleaded, that had been dosed with Castrol Valvemaster, into the 2 gallon tank. After a few tentative prods (I wasn't sure yet where the advance/retard lever needed to be set) I gave it a heft kick and she fired up. Yippee... Oh... hang on... The ammeter isn't showing a charge. With the lights switched on, there was a very definite discharge which revving the engine did nothing to alleviate. Bummer!!

I was confident that the dynamo was working. It ran as a motor when I tested it a few of weeks ago so it should work as a generator when being driven. Time for a little investigative probing. I disconnected the two wires from the dynamo and with the D & F connected to each other and my multi-meter, with the engine running, the voltage output rose steadily to around 20v as the engine revved higher. So... the dynamo was in fact working correctly. I'd noticed that the two connections to the dynamo weren't really that good. The wires just wrap around a little brass bullet and plug into the dynamo. I made up a couple of more secure crimp terminals, cleaned the dynamo connectors and connected the whole lot up again. This time, with the headlight on main beam, the ammeter was showing a healthy charge at a fast tick-over. Splendid... That just leaves the seat to put back when it arrives.

Wednesday, 25th March, 2020.

The recovered seat arrived yesterday and was duly bolted back on. It looks good. Well, that's about it... The bike is now ready for the road. Unfortunately, the Coronavirus pandemic has forced me to put the bike back in the garage until such time as the restrictions on unessential travel are lifted. What a bummer!!

Thursday, 23th April, 2020.

After a month in "lock-down" because of the Covid-19 pandemic, I was going a bit "stir crazy". So this morning I thought enough was enough and I pulled the G80 out of the garage. I figured a short ride up to Gedney Drove End wouldn't do any harm. I'm allowed to cycle up there for exercise and the roads are always deserted. As it happened, I didn't get that far... just to the end of my road. When I rebuilt the gearbox, one of the worn bits I replaced was the detent plunger. I had trouble getting one the correct diameter and, it seems, the new one also has a revised shape at the pointy end. What it means is that the new plunger doesn't just act as a detent to stop the bike jumping out of gear, it effectively locks the selector drum in place and I couldn't change gear. I knew it was a bit 'stiff' but thought it would ease up with a few miles on the clock. In fact, I found I could go up through the gears with a good hard push down with my foot but I couldn't persuade it to come down through the gears. I stopped at the end of my road and it took successive upwards tugs with my hand to persuade the box to engage first gear again. I turned around and drove back home.... the shortest ride out in history!!. So... The bike will be back in the workshop tomorrow to get that little problem sorted.

Sunday, 26th July, 2020.

I've been a bit lax keeping this page up to date but things have moved on quite a bit. The gear selector drum problem was sorted relatively easily. I stripped out the detent plunger and carefully re-profiled the end. I put a larger radius on and then polished it. That did the job and the gear change was much better on the next ride out. Unfortunately, the same could not be said for the speedometer. It worked fine for the first 20 miles then started to become erratic, the needle swinging all over the dial. I telephoned Russell at Chronometric Instrument Services as it was under warranty. He reckoned the most likely cause was grease contamination of the clutches, probably scrolled up from the old cable into the speedometer head. The speedo head went back to Russell and I ordered a new dive cable from AMOC Spares. That first ride out also convinced me that a new carburettor was needed. The 64 year old original was very worn, making tuning it for slow running almost impossible. A new one was subsequently ordered from Burlen and duly fitted. That made a huge improvement to the ride quality.

Talking of clutches, I had noticed that the clutch plates were prone to sticking together. The pressure plate was free of the clutch pack by at least 3mm with the handlebar lever pulled fully in so there was no reason why the clutch shouldn't be free but with the lever pulled in and kicking the engine over against compression, I couldn't get the plates to separate. Starting the engine, holding in the clutch lever and front brake hard on, then putting the bike into gear separated the plates and we were good to go. A 150 mile round trip to the Strathmore Arms convinced me that the clutch would need some more looking at. The plates were reluctant to free correctly, even with the engine hot, making gear changes a bit "crunchy".

The clutch problem would have to wait a while longer as the coronavirus lock-down, my lady Christine, and more pressing work on my other bikes had to take priority. Finally, a few days ago, the G80CS was back in the workshop and up on the bench. It all started off reasonably well but then stared to go downhill. Having removed the clutch dome on the primary chain case and stripped out the clutch plates, I could tell that they were the original items... the friction plates had the old individual inserts, not the later bonded segments. They were also pretty worn and some of the friction segments were loose. Time, I think, to bin the lot and replace them all. I'd ordered a new set of Surflex friction plates off the Internet and a set of the plain steel plates from AMOC Spares. While I was waiting for the new clutch plates to arrive, I stripped off the primary chain case outer cover. Just as well I did as a number of small chunks of metal fell out into the tray I'd placed to catch the oil... broken rollers from the primary chain. I hadn't seen that coming... So, a new primary chain was ordered and I ordered a new dynamo drive chain while I was at it.

I wanted to establish where the oil that dripped after a ride out was coming from so I stripped off the clutch basket and hub, undid the crankshaft nut and took off the engine sprocket and shock absorber. I noticed that this competition machine had an 18 tooth engine sprocket as standard, unlike the 'touring' 500 that has a 21 tooth sprocket. It was in good condition so I couldn't really justify replacing it. Once the inner chain case was removed, I could see where a lot of the oil was coming from... The oil seal behind the gearbox sprocket. Ho hum...

Friday, 14th August, 2020.

To get at the oil seal I had to remove the sprocket. It was then that I found that the sprocket securing nut was barely finger tight. All that was stopping it from undoing itself completely was the locking tab washer and the tangs on that were almost completely worn away. Looks like I got there just in time!. The standard 16 tooth final drive sprocket was very worn so I'll take the opportunity to replace it with a 19 tooth sprocket which will compensate for the smaller engine sprocket and bring the gearing back up close to the touring model. That will necessitate a new final drive chain, of course.

To get at the oil seal I had to remove the sprocket. It was then that I found that the sprocket securing nut was barely finger tight. All that was stopping it from undoing itself completely was the locking tab washer and the tangs on that were almost completely worn away. Looks like I got there just in time!. The standard 16 tooth final drive sprocket was very worn so I'll take the opportunity to replace it with a 19 tooth sprocket which will compensate for the smaller engine sprocket and bring the gearing back up close to the touring model. That will necessitate a new final drive chain, of course.

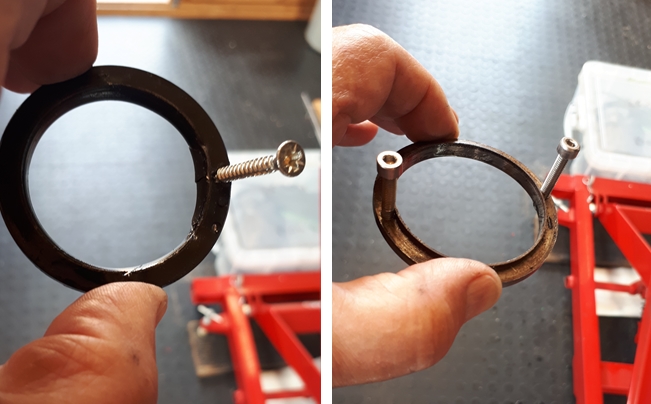

Replacing the gearbox oil seal is straightforward enough but not without it's difficulties if the gearbox is still mounted in the bike. The seal is pressed into a steel "carrier ring" which in turn is secured into the gearbox by a large circlip. Removing the circlip is easy enough but getting the seal assembly out of the gearbox is where it becomes tricky. You have to get a bit brutal. I drilled a small hole into the seal and screwed in a self tapping screw. A good hard tug and the seal came out, but not the steel carrier ring as I'd hoped.  That left me with a problem; I could leave the old ring in place and try to push the new seal into it or I could try to remove the old carrier ring. As I had a new one to hand, I decided to use a similar method to remove the old ring. I carefully drilled two 3.3mm holes in the carrier, going through until the drill stopped against the outer ring of the ball bearing that was behind it. I used a flat bottomed drill to clear out the holes and then tapped them M4. Two M4 cap heads were then screwed in and as they pushed against the ball bearing outer ring, they actually drove the carrier ring out. Result!! The whole lot was reassembled, using new locking tab washers where appropriate. A short test ride of 30 miles or so showed that the new clutch was much better, freeing up easily. The new 19 tooth final drive sprocket improved things no end. The engine was a lot less 'busy' and cruising at 60-70 m.p.h. was easy.

That left me with a problem; I could leave the old ring in place and try to push the new seal into it or I could try to remove the old carrier ring. As I had a new one to hand, I decided to use a similar method to remove the old ring. I carefully drilled two 3.3mm holes in the carrier, going through until the drill stopped against the outer ring of the ball bearing that was behind it. I used a flat bottomed drill to clear out the holes and then tapped them M4. Two M4 cap heads were then screwed in and as they pushed against the ball bearing outer ring, they actually drove the carrier ring out. Result!! The whole lot was reassembled, using new locking tab washers where appropriate. A short test ride of 30 miles or so showed that the new clutch was much better, freeing up easily. The new 19 tooth final drive sprocket improved things no end. The engine was a lot less 'busy' and cruising at 60-70 m.p.h. was easy.

Wednesday, 19th August, 2020.

Right... lets go back a bit. While the chronometric speedometer was back with Russell to be sorted out the first time, I fitted a Smiths electronic speedometer, similar to the instruments that I have fitted to my '71 Bonneville. Rather than write about that installation here, I've documented it all on a separate web page which you will find in the links below. Let's just say that it didn't all go to plan and I ended up swapping backwards and forwards between the two instruments. Currently, as I write this on the 19th August 2020, the chronometric instrument has been returned to Russell yet again and the G80CS has the electronic speedometer fitted so that I can use the bike. When I get the chronometric instrument back, I'll give it a thorough workout on the bench. If it's OK, then I'll put it back on the bike as I would like to keep it at least reasonably 'original'.

Wednesday, 10th March, 2021.

With the winter all but over and the Covid-19 problem seemingly under control, it was time to have another look at the G80CS. I finally gave up trying to get the chronometric speedometer working perfectly, so I settled on a compromise. The speed indication is perfect. The total odometer also seems to record reliably. The trip odometer works but seems to stop recording when the bike is ridden hard. It's the same problem I had with the G3/LS and I can only put it down to vibration. I really can't be arsed to keep sending it back to Russell and will just accept it as it is. According to a few people on the AMOC forum, it's not an unknown problem.

Right... I managed to get the CS out a couple of days ago and ride it around my 35 mile "test circuit". The handling round the rural lanes, with a less than perfectly maintained surface, was 'interesting' to say the least. The Mitas knobbly tyres and a 21" front wheel make barreling into twisty bits at a rate of knots somewhat hazardous to your general wellbeing to say nothing of your under-pants. I had a good look around the bike when I got it back home and up on the bench. There's no play in the wheel bearings, swinging arm pivot or the steering head bearings but there is evidence that the front forks and "Jampot" rear suspension units have been leaking oil for some time. There's probably not a lot, if any, oil left in them so damping would be minimal. I think it's time to rebuild the lot.

As "Jampot" rear suspension units and "Teledraulic" front forks and not unique to the G80CS but fitted to most AMC machines from 1951 to 1956, I'll not document the rebuild on this page but create dedicated pages for the rebuilds. When they're finished, you'll be able to access them from the links on the "Motorcycle Stuff" page.

Tuesday, 16th March, 2021. The "Jampots" have been rebuilt and are now back on the bike. In truth, they weren't in that bad a condition. There was some oil still left in them but not much. Enough, fortunately, to stop them destroying themselves. The oil seals were hard and worn. They've been replaced with new, double lip seals. The plastic bushes have been replaced with better quality bronze items, and all the other seals and sealing washers have been replaced as a matter of course. Both units now contain the correct quantity of new 20W fork oil. Having finished those, I'll start on the front forks.

Wednesday, 7th August, 2024. To be truthful, the front forks never got rebuilt. They are still as they were when I bought the bike.  Having said that, the bike hasn't been ridden much either in the last couple of years. It has had two or three runs out to the Strathmore Arms and we did attend a "Classic" meeting at the Five Bells in Tydd St. Mary, but that's been about it!

Having said that, the bike hasn't been ridden much either in the last couple of years. It has had two or three runs out to the Strathmore Arms and we did attend a "Classic" meeting at the Five Bells in Tydd St. Mary, but that's been about it!

Last Wednesday, I thought it was time for another run down to see my mate, Les, at the Strathmore Arms and decided to take the G80CS. I probably should have given it a little more that a 'quick once-over' before setting off. I soon noticed that the throttle cable was a little stiff and reluctant to 'snap shut' when I released the twist grip. That culminated with the throttle being held open, the bike doing 60 m.p.h. and a corner fast approaching. I did manage to get it stopped without too much drama but it was a bit close!! The split collar where the cable enters the twist grip and become jammed, holding the throttle slide about 1/4 open. Almost certainly my fault through poor maintenance. The cable was dry and in need of some lubrication. The problem was soon sorted with the help of the friendly guy outside of who's house I had stopped. I wrapped a few turns of electrical insulation tape around it to keep it in place. It was ok for the rest of the ride.

I had also noticed that the petrol tank was vibrating against the frame somewhere. That needed to be sorted as the tank is aluminium and I don't want it damaged and causing a leak. So now the bike is in the work shop. The cable problem has been sorted. It's been well lubricated and the split collar has been secured with a small length of heat shrink tubing in place of the insulation tape. The tank has been removed and it would appear that it's been resting on the top frame tube. The paint has been rubbed off, but there is no significant damage. The easiest fix is to lift the tank a little. The rear of the tank is fixed through a hole in the frame and that isn't easy to move but I have a couple of 6mm thick rubber washers that are exactly the right size to put under the front mountings and that should lift the tank enough so that it no longer rubs on the top frame tube. That was the easy bit. With those rubber washers in place, the mounting studs were now not long enough to get a normal nut on when the tank was positioned on the frame. What I needed was a pair of sleeve or shouldered 3/8" BSF nuts. Not something I expected to find easily. I was wrong... they are readily available. It would seem that they are used on the Lucas 'Mag-Dyno' fitted to some BSA bikes. I ordered a pair and they arrived a couple of days ago. I had to shorten them very slightly and modify a couple of large stainless washers but they will do the job nicely.

It's been well lubricated and the split collar has been secured with a small length of heat shrink tubing in place of the insulation tape. The tank has been removed and it would appear that it's been resting on the top frame tube. The paint has been rubbed off, but there is no significant damage. The easiest fix is to lift the tank a little. The rear of the tank is fixed through a hole in the frame and that isn't easy to move but I have a couple of 6mm thick rubber washers that are exactly the right size to put under the front mountings and that should lift the tank enough so that it no longer rubs on the top frame tube. That was the easy bit. With those rubber washers in place, the mounting studs were now not long enough to get a normal nut on when the tank was positioned on the frame. What I needed was a pair of sleeve or shouldered 3/8" BSF nuts. Not something I expected to find easily. I was wrong... they are readily available. It would seem that they are used on the Lucas 'Mag-Dyno' fitted to some BSA bikes. I ordered a pair and they arrived a couple of days ago. I had to shorten them very slightly and modify a couple of large stainless washers but they will do the job nicely.

While I was working on the bike I got to thinking about the throttle sticking open. The only way I have to stop the engine is to operate the exhaust valve lifter, effectively a de-compressor. That's ok when the bike is stationary and the engine is ticking over but I was a bit reluctant to use it with the bike doing 60 m.p.h. and the engine probably doing 4500 r.p.m. The valve train could have been damaged if the pushrod had become unseated and jammed. It would have been much better to just turn off the ignition. This bike has a magneto, not coil ignition, and there is no ignition switch. However... you can fit a push button 'Kill Switch'. It means buying a different, screw-on points cover for the Lucas NC1 competition magneto that has the necessary electrical connection, and a handlebar mounted push button, but they are available, and have been ordered. It seemed a reasonable modification while the bike is in the workshop.

I had another thought... two in one day, what's going on? While the tank was off and access was easy, why not check the valve clearances? With the 'touring' G80, the valve clearance is zero... that is, with the piston at T.D.C. on the compression stroke, the pushrods should be free to rotate but with no discernible up and down movement. This, however, is a competition engine and I wasn't sure that the settings are the same. A quick check with the guys on the AMOC Forum and I had the answer. The inlet is the same, i.e. zero clearance, but the exhaust should have 0.005" clearance. The way to set that, is to set it at zero, then back the adjuster off by one flat of the hexagonal nut to give the required 5 thou. With that knowledge, I whipped off the inspection cover, set the piston to T.D.C. and attempted to rotate the pushrods. They were both too tight. There was no up and down movement but I couldn't rotate them either. I've reset them as per the instructions.

Tuesday, 3rd September, 2024. The handlebar push button "kill switch" arrived over the weekend, finally. I hadn't realised that it was coming from China when I ordered it. The connections have been made, the tank and seat re-installed. The bike started and ran ok. It stopped immediately when the button was pressed. There was no indication that the tank was touching the frame anymore, so that all seems ok, too. I'll know better when I take her out for a road test. The sleeve nuts that now hold down the front of the tank have been drilled and wire-locked for security.

Link to Index and Home Page.

Link to Triumph Tiger 90 page.

Link to Triumph Bonneville T120R page.

Link to AJS M18S page.

Link to Matchless G3/LS page.

Link to Honda VFR750 page.

Link to Norton 650SS page.

Last updated 03/09/2024