The first and most immediate problem was mounting the speedometer. The drive cable connection on the original was offset from the centre so the original mount was a simple "L" shaped bracket with a couple of 6mm holes for the mounting screws. The new speedometer has the cable entry slap bang in the centre so I couldn't use the original mounting bracket… at least, not without modifying it. So, I did… modify it, that is. The original bracket was cut, a new piece for the centre fabricated and the whole lot brazed together again. A couple of coats of black paint and the job's a good 'un.

The first and most immediate problem was mounting the speedometer. The drive cable connection on the original was offset from the centre so the original mount was a simple "L" shaped bracket with a couple of 6mm holes for the mounting screws. The new speedometer has the cable entry slap bang in the centre so I couldn't use the original mounting bracket… at least, not without modifying it. So, I did… modify it, that is. The original bracket was cut, a new piece for the centre fabricated and the whole lot brazed together again. A couple of coats of black paint and the job's a good 'un.

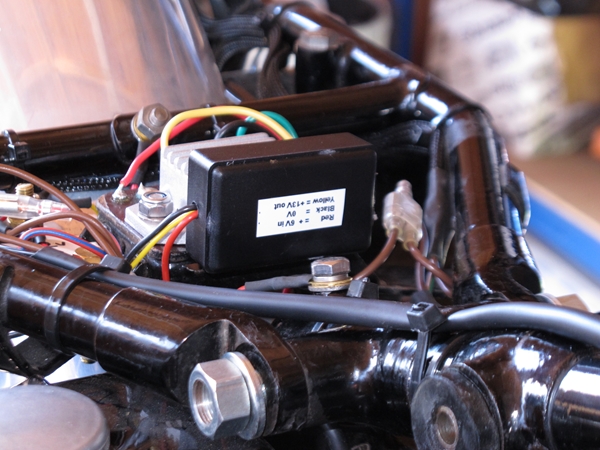

OK… with the speedo mounted, it was time to address the problems mentioned earlier. Could I sort out the power and wiring issues…? Of course I could, I was an engineer, once, long ago!!! Converting 6 volts to 12 volts was the easy bit. With the wizardry of modern electronics, a bit of Googling, and a modest payment, I soon had a "little black box" that did the job for me.  I'm reliably informed that the box is home to an enchanted Imp who upset a local sorcerer. It will forever suck in 6 volts from one end and fart out 12 volts at the other. Brilliant. It was duly mounted under the seat and connected up. It won't supply enough power to run 12 volt headlights but it will supply enough to run the speedometer. All I had to do now was keep the 12 volts isolated from the frame. Fortunately, the speedometer's metal case is isolated electrically from the internal gubbins so that being mounted on the frame didn't matter. All the other electrical connections could be made with insulated bullet connectors so the reversed polarity wouldn't matter either, provided the two circuits never came into contact with each other. So far, so good. That just left the "turning off" thing to sort out. In the end, that was easy enough, too. For safety reasons, I never ride any of my bikes without the lights being turned on, even in daylight, so I used the original speedometer's illumination connection to supply power to the system. When the lights are tuned on, the speedometer powers up. Simples. So… did it all work? Yes, of course it did.

I'm reliably informed that the box is home to an enchanted Imp who upset a local sorcerer. It will forever suck in 6 volts from one end and fart out 12 volts at the other. Brilliant. It was duly mounted under the seat and connected up. It won't supply enough power to run 12 volt headlights but it will supply enough to run the speedometer. All I had to do now was keep the 12 volts isolated from the frame. Fortunately, the speedometer's metal case is isolated electrically from the internal gubbins so that being mounted on the frame didn't matter. All the other electrical connections could be made with insulated bullet connectors so the reversed polarity wouldn't matter either, provided the two circuits never came into contact with each other. So far, so good. That just left the "turning off" thing to sort out. In the end, that was easy enough, too. For safety reasons, I never ride any of my bikes without the lights being turned on, even in daylight, so I used the original speedometer's illumination connection to supply power to the system. When the lights are tuned on, the speedometer powers up. Simples. So… did it all work? Yes, of course it did.

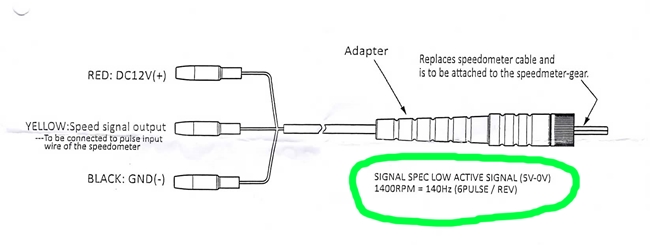

All I needed to do now was to 'calibrate' the speedometer. Along with the speedometer head, I also bought a "Speed Pulse Converter". This SPC screwed into the original speedometer drive gearbox on the rear wheel in place of the cable that would originally have been used.  This little device is driven by the gearbox and delivers a square wave output, at 6 pulses per revolution, into the square wave signal input of the speedometer. The preferred method of calibration is to use the in-built "Drive To Measure" function. For this, you put the speedometer into DTM mode and then drive for exactly one mile. The speedometer counts the number of pulses it receives from the SPC and uses that number as the "PPU" (pulses per unit… in this case, pulses per mile) for all future speed / distance calculations. Easy, peasy… if you have a pre-measured stretch of road that is exactly one mile long. They happen to be rarer than hen's teeth in rural Lincolnshire. Fortunately, it's possible to input the PPU manually. It's a bit fiddly but it can be done. First off, you need to know what the PPU number is. This is the way I calculated it…

This little device is driven by the gearbox and delivers a square wave output, at 6 pulses per revolution, into the square wave signal input of the speedometer. The preferred method of calibration is to use the in-built "Drive To Measure" function. For this, you put the speedometer into DTM mode and then drive for exactly one mile. The speedometer counts the number of pulses it receives from the SPC and uses that number as the "PPU" (pulses per unit… in this case, pulses per mile) for all future speed / distance calculations. Easy, peasy… if you have a pre-measured stretch of road that is exactly one mile long. They happen to be rarer than hen's teeth in rural Lincolnshire. Fortunately, it's possible to input the PPU manually. It's a bit fiddly but it can be done. First off, you need to know what the PPU number is. This is the way I calculated it…

I wrapped a tape measure around the rear tyre… that gave me a figure of 88" for the circumference. Dividing 63,360 (inches in a mile) by 88 will give me the number of rotations of the rear wheel for one mile travelled; in this case 720. OK… I know it won't be absolutely accurate, due to the tyre flexing while you ride, but it will get me into the right ballpark. The drive gearbox on the rear wheel has a ratio of 2:1 so the speed pulse converter will rotate 1440 times per mile. The SPC gives 6 pulses per revolution so all being well, we'll get 8,640 pulses per mile. That is the number I programmed into the speedometer. It was reassuringly close to the number that had been pre-programmed into the speedometer at the factory. I've mounted my GPS receiver on the handlebars. That will give me an accurate measurement of the bike speed in real time and also record it. I will compare the two readings, GPS and speedometer, and adjust the PPU number accordingly. If the speedometer is indicating a slower speed than the GPS, I'll reduce the PPU by the appropriate amount. If the speedometer is indicating a higher speed than the GPS then I'll increase the PPU. I did exactly this when I installed the electronic speedometer on the Bonneville. It took just one adjustment of the PPU for the speedometer to read exactly the same as the GPS. Hopefully, I'll be able to say the same for the G80CS.

The drive gearbox on the rear wheel has a ratio of 2:1 so the speed pulse converter will rotate 1440 times per mile. The SPC gives 6 pulses per revolution so all being well, we'll get 8,640 pulses per mile. That is the number I programmed into the speedometer. It was reassuringly close to the number that had been pre-programmed into the speedometer at the factory. I've mounted my GPS receiver on the handlebars. That will give me an accurate measurement of the bike speed in real time and also record it. I will compare the two readings, GPS and speedometer, and adjust the PPU number accordingly. If the speedometer is indicating a slower speed than the GPS, I'll reduce the PPU by the appropriate amount. If the speedometer is indicating a higher speed than the GPS then I'll increase the PPU. I did exactly this when I installed the electronic speedometer on the Bonneville. It took just one adjustment of the PPU for the speedometer to read exactly the same as the GPS. Hopefully, I'll be able to say the same for the G80CS.

Don't you just hate it when you get duff information supplied with something you've just bought. You trust it, only to find that whatever it is you've bought doesn't function as it should because they've lied to you!! I will elucidate... The information sheet that came with the speed pulse converter clearly states that the output is 6 pulses per revolution. I took that at face value and calculated the PPU number to be 8640 and programmed that number into the speedometer. With the bike firmly strapped down onto the work bench and the rear wheel clear of the ground, I started her up, put it into 1st gear and let the clutch out. I gave it some revs, expecting the speedometer to indicate at least a low speed.. but there was nothing, not a flicker! I revved it harder but still nothing even though the rear wheel was spinning quite fast. I shut it all down, just a little dejected. I went through all the connections again to check that I'd not done anything stupid... I hadn't so I started her up again, banged it straight through into top gear and gave gave her some beans. With the engine revving pretty damn fast, I noticed that the speedometer was now indicating around 10 m.p.h. Hmmm.... I wonder??

The information sheet that came with the speed pulse converter clearly states that the output is 6 pulses per revolution. I took that at face value and calculated the PPU number to be 8640 and programmed that number into the speedometer. With the bike firmly strapped down onto the work bench and the rear wheel clear of the ground, I started her up, put it into 1st gear and let the clutch out. I gave it some revs, expecting the speedometer to indicate at least a low speed.. but there was nothing, not a flicker! I revved it harder but still nothing even though the rear wheel was spinning quite fast. I shut it all down, just a little dejected. I went through all the connections again to check that I'd not done anything stupid... I hadn't so I started her up again, banged it straight through into top gear and gave gave her some beans. With the engine revving pretty damn fast, I noticed that the speedometer was now indicating around 10 m.p.h. Hmmm.... I wonder??

I reckon that the bike would have been doing around 60 m.p.h. in top gear at the revs the engine was pulling. (I'm mightily glad the bike didn't come off the work bench!!) The speedometer was indicating a 6th of that. When I fitted a similar system to the Bonneville, the SPC only gave out 1 pulse per revolution. Could it be that simple? I assumed that the SPC was giving 1 pulse per rev and reprogrammed the PPU to 1440. That gave an immediate improvement. I got an indication in first gear and it was now indicating around 50 m.p.h. with the bike revving in top gear. We were in the right ball park so time for a test ride and a comparison with the GPS on the handlebar. I took her out of the village and onto South Drove which is virtually dead straight for 2 miles. With the speedometer indicating a steady 50 m.p.h. the GPS was showing 44.6 - 45.2 m.p.h. Call it 45 m.p.h. I stopped and reprogrammed the PPU number again. The speedometer was reading faster than I was actually travelling, so the PPU number needed to be increased. A simple calculation (1440 x 50 / 45 = 1600) and that was programmed in. Another run up South Drove and now the speedometer and the GPS were exactly in sync. Finally got there... Yippeee!!!

Ho hum... Things didn't work out quite as I'd hoped. A 150 mile round trip to The Strathmore Arms was on the cards so I decided it would be a good run out for the G80CS. All went well for the first 40 miles or so then the speedometer started to get 'erratic', the needle was dropping back to zero for a few seconds before returning to roughly the correct speed. It gradually got worse until it became completely useless as a speed indicator. Fortunately, I still had the GPSr mounted on the handlebars so I had to use that as my speedometer. The return journey was more of the same with the final humiliation coming just half a mile from home when the mounting bracket broke and I ended up holding the speedo in place for the last couple of hundred yards. Bummer and bummer again!!

Ho hum... Things didn't work out quite as I'd hoped. A 150 mile round trip to The Strathmore Arms was on the cards so I decided it would be a good run out for the G80CS. All went well for the first 40 miles or so then the speedometer started to get 'erratic', the needle was dropping back to zero for a few seconds before returning to roughly the correct speed. It gradually got worse until it became completely useless as a speed indicator. Fortunately, I still had the GPSr mounted on the handlebars so I had to use that as my speedometer. The return journey was more of the same with the final humiliation coming just half a mile from home when the mounting bracket broke and I ended up holding the speedo in place for the last couple of hundred yards. Bummer and bummer again!!

Time for Plan "B"... Electronics don't usually give intermittent faults... They either work or they don't so I suspected that it was more likely to be the mechanical part of the speed pulse converter at fault rather than the speedometer itself. I took the SPC off and sent it back to Digital Speedometers along with a covering letter describing what had happened. Two days later I got a phone call from one of their engineers. They had tested the SPC, and it was working perfectly. There was, however, a problem. It seems that the SPC wasn't really compatible with the classic rear wheel drive gearbox.  The square section input shaft that locates where the normal inner speedometer cable goes was too small and tended to slip, hence the erratic reading on the speedometer. They had modified it and were sending it back to me. They also confirmed that it was, in fact, 1 pulse per revolution. I had apparently been sent the wrong information sheet. The SPC arrived the next morning and looked exactly as I remembered the Bonneville one looking a few years ago. Hopefully, that has sorted one problem; now I had to work out how to mount it reliably. The original simple bracket was obviously not going to be strong enough. The solution was actually very simple. The '71 Bonneville had instruments mounted in rubber cups, supported in chrome plated rings that were secured under the front fork leg cap nuts. When I rebuilt the Bonnie, I mounted the instruments on a custom made plate... The original mounts were in a box in the garage. I picked the best one, fitted the digital speedometer into it and fitted it under the left hand fork cap nut on the G80CS. I had to turn up a spacing ring to go under the mounting plate but in the end, it was an easy, if not very elegant, fix. Hopefully, it will not be a long term solution as I now have an original chronometric instrument that is currently with Russell at Chronometric Instrument Services being given a "Concourse Restoration". That will be fitted in due course (or maybe, I'll fit a matching tachometer under the other fork cap nut!!)

The square section input shaft that locates where the normal inner speedometer cable goes was too small and tended to slip, hence the erratic reading on the speedometer. They had modified it and were sending it back to me. They also confirmed that it was, in fact, 1 pulse per revolution. I had apparently been sent the wrong information sheet. The SPC arrived the next morning and looked exactly as I remembered the Bonneville one looking a few years ago. Hopefully, that has sorted one problem; now I had to work out how to mount it reliably. The original simple bracket was obviously not going to be strong enough. The solution was actually very simple. The '71 Bonneville had instruments mounted in rubber cups, supported in chrome plated rings that were secured under the front fork leg cap nuts. When I rebuilt the Bonnie, I mounted the instruments on a custom made plate... The original mounts were in a box in the garage. I picked the best one, fitted the digital speedometer into it and fitted it under the left hand fork cap nut on the G80CS. I had to turn up a spacing ring to go under the mounting plate but in the end, it was an easy, if not very elegant, fix. Hopefully, it will not be a long term solution as I now have an original chronometric instrument that is currently with Russell at Chronometric Instrument Services being given a "Concourse Restoration". That will be fitted in due course (or maybe, I'll fit a matching tachometer under the other fork cap nut!!)

Another run around my 30 mile 'test route' showed that after an initial erratic few seconds while it sorted itself out, the speedometer worked perfectly, so for the moment, I'm happy.

Last updated 03/02/2021